Fertilizer granulator machine is designed for different type and series.And different type and series fertilizer granulator machine to be used to produce fertilizer granulator in different producing method.Different type and model to be designed,like the

roller press granulator,ring die granulator,flat die granulator and disc granulator and so on.There we share the rotary drum granulator how to work.

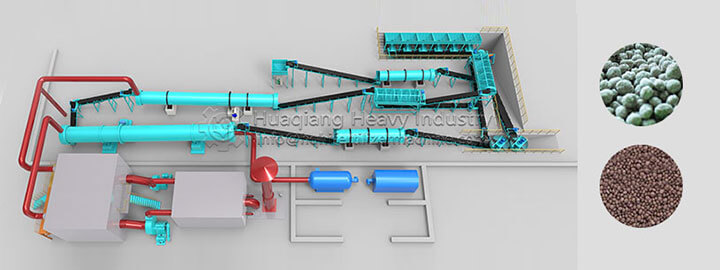

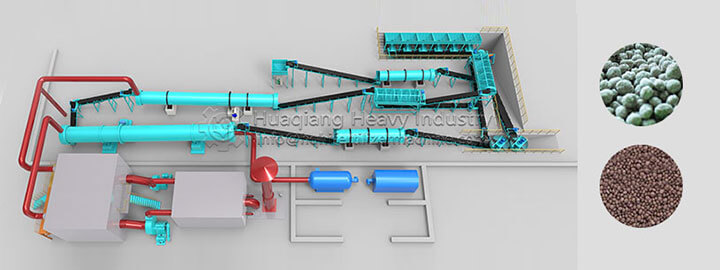

Rotary drum granulator machine is a kind of forming machine which can make materials into specific shapes.The drum granulator is one of the key equipment in the compound fertilizer industry,which is suitable for cold and hot granulation and large-scale production of high,medium and low concentration compound fertilizer.The main working mode is wet granulation of pellets.Through a certain amount of water or steam,the basic fertilizer can be fully chemically reacted after being humidified in the cylinder.Under a certain liquid phase condition,with the help of the roating motion of the cylinder,the extrusion pressure between the particles of the materials can be generated to agglomerate into a ball.

Features of

rotary drum granulator:

1.The pelletizing rate is up to 70%,there is a small amount of returned material,the particle size of returned material is small,and it can be repelletilized;

2.Through steam heating,the temperature of the material is increased,the moisture content of the material after balling is low,and the drying efficiency is improved;

3.With rubber engineering plastics as lining,the raw materails is not easy to stick to the cylinder,and plays the role of anti-corrosion and heat preservation;

4.Large output,low power consumption,low maintenance cost.

In the

fertilizer manufacturing process,when granulating granular,the fertilizer granulator machine is a factor equipment.Choosing the suitable fertilizer machine to make fertilizer granulator.How to work of the rotary drum granulator?

The working principle of this series of rotary drum granulator is that the belt and pulley are driven by the main motor,transmitted to the driving shaft through the reducer,and the split gear installed on the driving shaft is matched with the big gear ring fixed on the body to work in the opposite direction.The material is added from the feed end to the inside of the barrel.Through the function of the specifical structure inside the cylinder,it is made into particles,and finally flows out through the discharge port.Due to the continuous entry of materials and the continuous rotation of granulator,mass production can be realized.