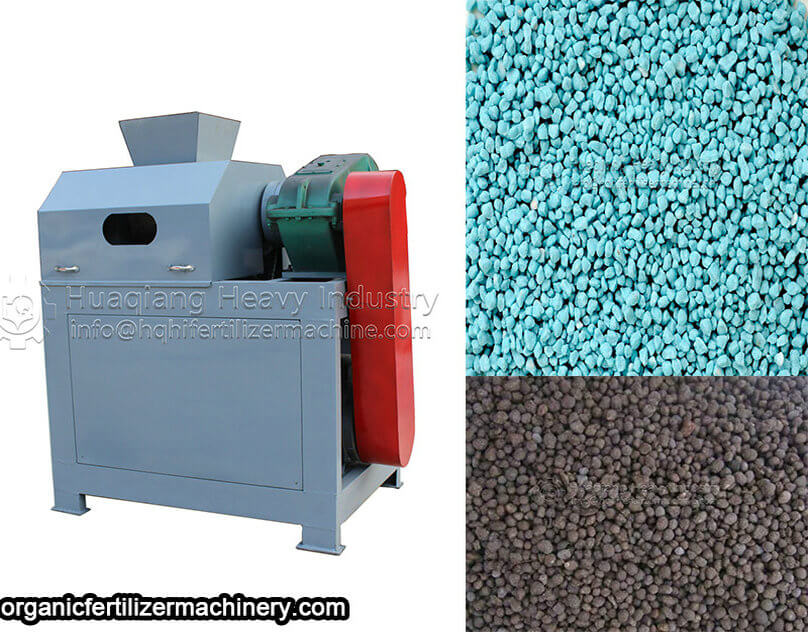

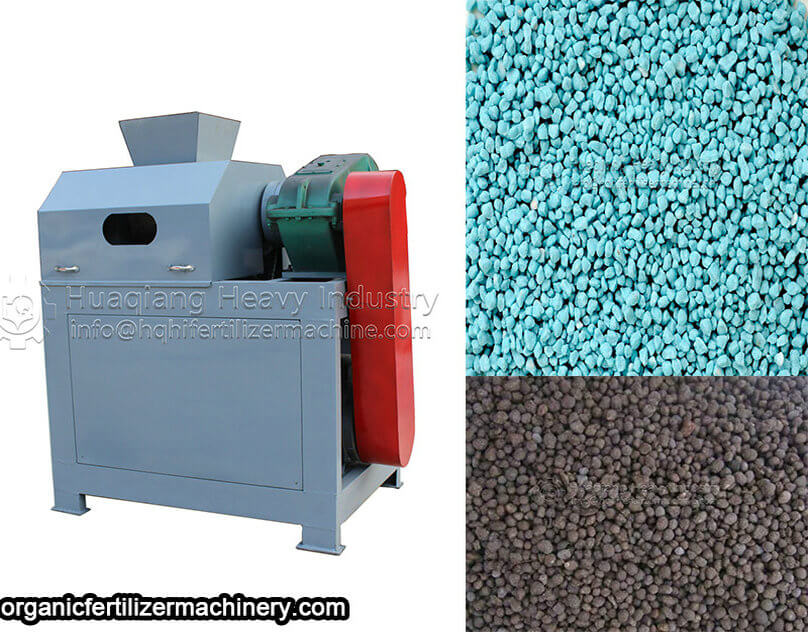

How to make fertilizer granulator?Using different type fertilizer granulator has different type granulating method in the fertilizer granulating process.The process principle of

roller press granulator.

Dry materials agglomerate into compact and hard bulk (cake) under pressure,which is called extrusion process;the cake material is broken and screened to become granular material,which is called granulation process.The function of extrusion is to expel the air between particle,and to make the distance between particles close enough to produce attraction such as van der waals force,adsorption force,crystal bridge and embedded connection.The particle strength of extrusion granulation is mainly formed by the force between molecules.

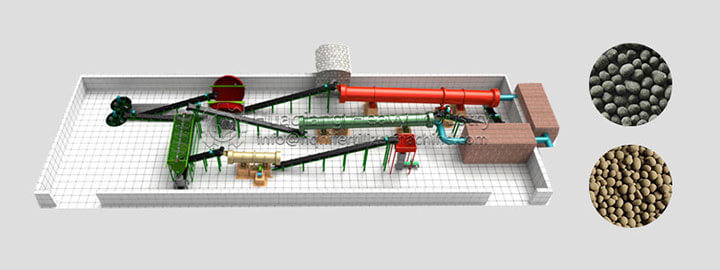

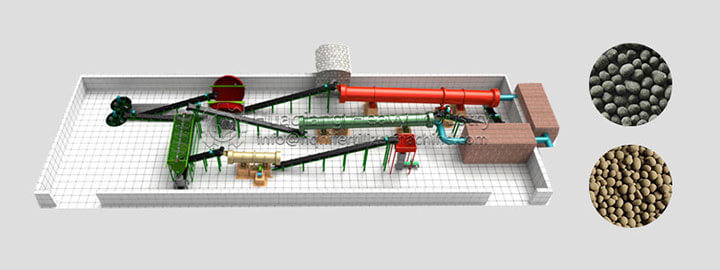

The roller prss granulator machine is usually to be used in npk,compound fertilizer production line to make compound fertilizer granulator.By the way,beside the roller press granulator to be used in the line,the

rotary drum granulator machine also can be used in the production process.

.jpg)

Advantages of roller press granulator:

1)Engery saving and conssumption reducing extrusion granulation is the granulation of materials at room temperature.Compared with other methods,it does not need fuel oil,gas and other drying measures.

2)The production method of compound fertilizer which does not need to add binder is steam granulation.After condersation and cystallization between molecules,water vapor plays the role of binder in the process of manufacturing.However,in the drying process,the water inside and on the surface of the particles must be driven out,otherwise,the fertilizer is easy to bond and agglomerate in the storage process.Dry granulation does not need other additives,but only uses the intermolecular force of the material itself to simplify the process and reduce energy consumption.

3)The investment is low because the drying process is omitted and the return material ratio is low(accounting for about 15% of the total feeding amount of the extruder),the process low is simple and the investment is low.

4)There are more than 20 kinds of materials which have been successfully used in extrusion granulation:ammonium nitrate,urea,ammonium chloried,calcium nitrate,potassium chloride,potassium sulfate etc.In addition,the use of extrusion granulation process can flexibly change the product formula in a very short time.A set of device can produce more than 30 kinds of formula products.

The series

fertilizer granulator machine is usually to be used in compound fertilizer production line to produce the compound fertilizer granulator.The designing of the roller press granulator make the fertilizer granulator making is not so complex.

In a complete

fertilizer manufacturing process,making fertilizer granulator using the automatic or semi-automatic fertilizer machine can not only improve the working efficient,it also improve the rate of the raw materials.

.jpg)