The quality and effectiveness of organic fertilizer products directly depend on the operating status of the production equipment in the organic fertilizer production line and the suitability of the supporting processes. The factors affecting the quality of finished products from organic fertilizer production equipment are diverse and interconnected, but can be summarized into four core dimensions: raw material characteristics, performance of core equipment components, process parameter control, and operational management. These factors collectively determine key indicators such as nutrient content, particle morphology, and degree of decomposition of the finished product.

Raw material characteristics are the fundamental prerequisite. The type, moisture content, and carbon-to-nitrogen ratio of the raw materials directly affect the processing effect of the equipment. If the moisture content of the raw materials is too high, it will lead to insufficient fermentation and difficulty in granulation, resulting in finished products that are prone to clumping; if the moisture content is too low, it will cause poor material flow, increased equipment load, and low granulation rate. In addition, high impurity content in the raw materials will wear down equipment components and affect the purity of the finished product, while a reasonable carbon-to-nitrogen ratio is necessary to ensure efficient fermentation and balanced nutrient content in the finished product.

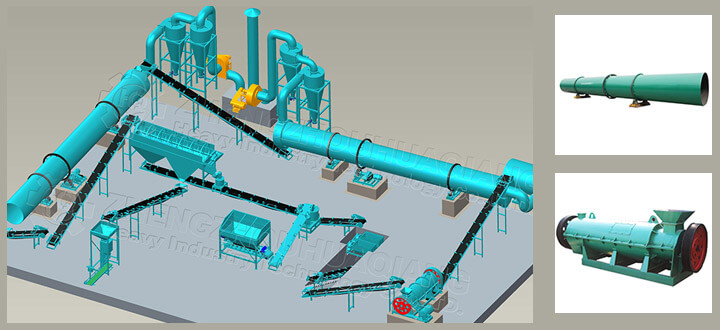

The performance of core equipment components is the core support. As key components of organic fertilizer machine, the crushing fineness of the crushing equipment, the mixing uniformity and aeration of the fermentation equipment, and the mold precision of the granulation equipment all directly affect the quality of the finished product. For example, incomplete crushing will lead to uneven material mixing and unbalanced nutrient distribution in the finished product; insufficient aeration in the fermentation equipment will cause anaerobic fermentation, resulting in unpleasant odors and substandard decomposition; and worn granulation molds will lead to uneven particle size and insufficient strength of the finished product, affecting storage and application.

Process parameter control is a crucial link. Precise control of parameters such as fermentation temperature, granulation speed, and drying temperature is essential. Too high a fermentation temperature can destroy nutrients in the raw materials, while too low a temperature will result in incomplete fermentation; too fast a granulation speed will result in excessively fine particles, while too slow a speed will result in excessively large particles with insufficient density; too high a drying temperature will cause nutrient loss, while too low a temperature will result in excessive moisture content in the finished product, making it prone to mold. The suitability of the parameters to the raw material characteristics and equipment performance directly determines the overall quality of the finished product.

Operational management is the guarantee. The professional level of the operators directly affects the stability of equipment operation and the accuracy of parameter control. Inadequate daily maintenance of equipment, such as worn bearings and conveyor belt misalignment, can lead to abnormal equipment operation and consequently affect the quality of the finished product. Lack of quality control during the production process allows substandard materials to enter subsequent stages, ultimately impacting the quality of the final product. Standardized operating procedures and regular equipment maintenance are crucial for ensuring the continuous and stable production of high-quality finished products.

In summary, the various factors affecting the quality of organic fertilizer produced by the equipment are interconnected and mutually influential. Only by accurately controlling raw material characteristics, ensuring equipment performance, optimizing process parameters, and strengthening operational management can the production equipment operate at its full potential and produce high-quality organic fertilizer.