In recent years, organic fertilizer production lines have experienced explosive market growth, becoming a popular piece of equipment in the green transformation of agriculture and the upgrading of the environmental protection industry. Their popularity is not accidental, but rather the result of a convergence of market demand, technological innovation, significant benefits, and industry trends. They not only meet the actual needs of high-quality agricultural production development, but also align with consumers' pursuit of green and safe products, and conform to the era's trend of circular economy development.

Upgrading agricultural and market demands constitute the core driving force behind this booming sales. For a long time, the over-reliance on chemical fertilizers in planting has led to soil compaction, fertility decline, and frequent pests and diseases. This not only affects crop yield and quality but also restricts sustainable agricultural development. Soil remediation and fertility improvement have become urgent needs in current agricultural production, and organic fertilizer, as a natural and environmentally friendly soil conditioner, has become key to solving this problem. At the same time, consumers' health awareness continues to rise, and the demand for green, organic, and pollution-free agricultural products is increasingly strong. Market acceptance and prices are constantly increasing, forcing growers, cooperatives, and agricultural enterprises to increase their investment in organic fertilizers, thereby promoting the expansion of organic fertilizer production scale and directly driving a surge in the purchase of organic fertilizer production lines.

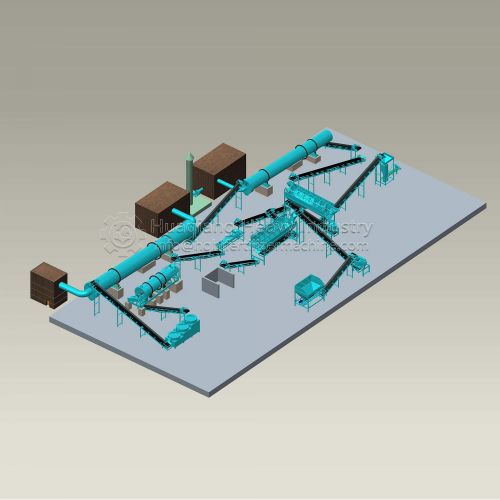

Technological innovation and considerable benefits enhance the core competitiveness of production lines. Compared to traditional small-scale workshops, modern organic fertilizer production lines have achieved a comprehensive upgrade. Through intelligent fermentation, efficient granulation, and precise drying systems, they significantly shorten the production cycle, reducing the fermentation process from dozens of days to just a few days. This effectively improves the quality of organic fertilizer, ensuring thorough decomposition and uniform nutrient distribution to meet the fertilization needs of different crops. Simultaneously, the new production lines adopt energy-saving and environmentally friendly designs, significantly reducing energy consumption. Exhaust gas and waste emissions meet environmental standards, eliminating the need for additional environmental treatment costs. Their modular and customizable design allows for flexible adaptation to the production needs of various scales, from family workshops and small and medium-sized enterprises to large-scale bases. With a reasonable investment threshold and a short payback period, they help producers reduce labor and material costs while generating additional revenue through the conversion of agricultural waste, making them the preferred equipment for improving quality and efficiency for all types of production entities.

Industry development trends continue to support the continued strong sales of these production lines. Today, green agriculture and circular agriculture have become the mainstream direction of agricultural development, and the promotion and use of organic fertilizer is an inevitable trend, providing a vast market space for organic fertilizer production lines. At the same time, the pace of large-scale and intensive agricultural development is accelerating, and the decentralized production model is gradually being replaced by centralized and standardized production, leading to a continuous increase in demand for efficient and intelligent organic fertilizer production lines.