The production method of commerical organic fertilizer granulator have different type.For different type raw material,producing the commerical organic fertilizer using different type fertilizer producing method.The

fertilizer manufacturing process also different to make different type fertilizer granulator.

Production of commerical organic fertilizer from animal manure:

A.High temperature quick drying method.High temperature gas is used to dry and granulate the stirred and tumbled wet chicken manure in the drying drum.The advantages of this method are:the odor is reduced,the harmful bacteria and eggs are killed,the treatment efficiency is high,and the factory production is easy.Disadvantages:poor maturity,killing some benefical microorganisms,and high engery consumption in the treatment process.

B.Oxidative cracking.The chicken manure was oxidized and cracked with strong oxygen agent,and the macromolecular organics in chicken manure were oxidized and cracked into active micromolecular organics.Advantages of the method:The product has high fertilizer efficiency and strong activation ability to the soil.Disadvantages:high cost and pollution.

C.Tower fermentation.The livestock manure is inoculated with microbial starter,stirred evenly,and then lifted to the tower type fermentation cabin by the conveying equipment.When fermenting,we can use the

fermentation compost turner machine to help to finish this work.In using this way can improve the working efficient and save the time of producing.In the tower,turn over,aerate,quickly ferment,deodorize,dehydrate,ventilate and dry,and the ongoing crusher will crush the large blocks,and then screen and pack them.The main equipment of the process includes mixer,hot blast furnace,conveying system,roller screen,crusher,electric control system,etc.The product has a high content of organic matter,a certain number of benefical microorganisms,which is conducive to improve the utilization rate of product nutrients and promoting the release of soil nutrients.

D.Mobile tossing fermentation process.In the greenhouse type fermentation workshop,the manure of livestock and polutry mixed with bacterial agent is continuously stirred along the track to ferment and dedorize.The manure of livestock and polutry enters from one end of the fermentation workshop and becomes fermented organic fertilizer when coming out,and directly enters the drying equipment for dehydration to become commerical organic fertilizer.The production process makes full use of light engery,fermentation heat,simple equipment and lower operation cost.Its main equipment is a dumper,a greenhouse,a cylinder,a dumper,etc.

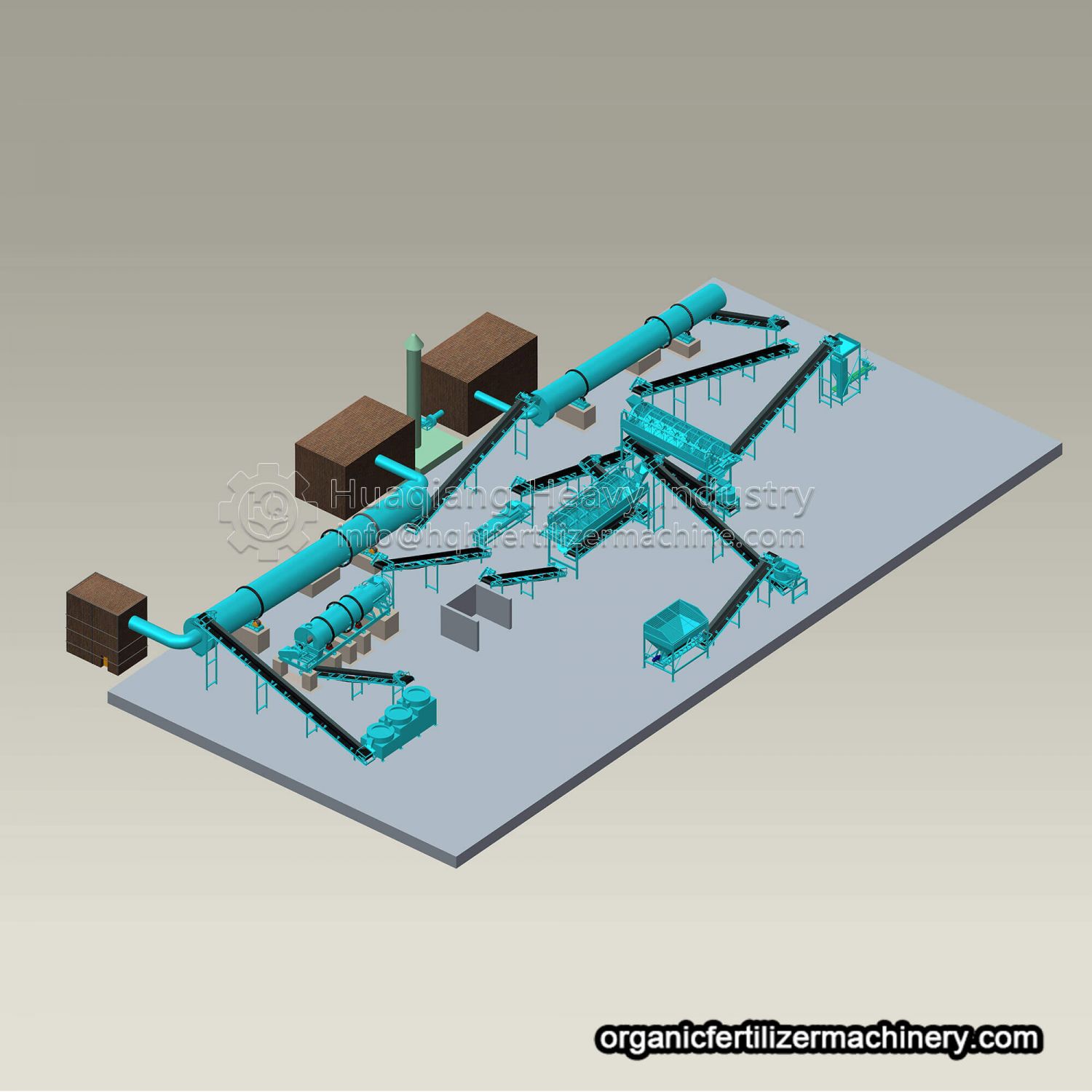

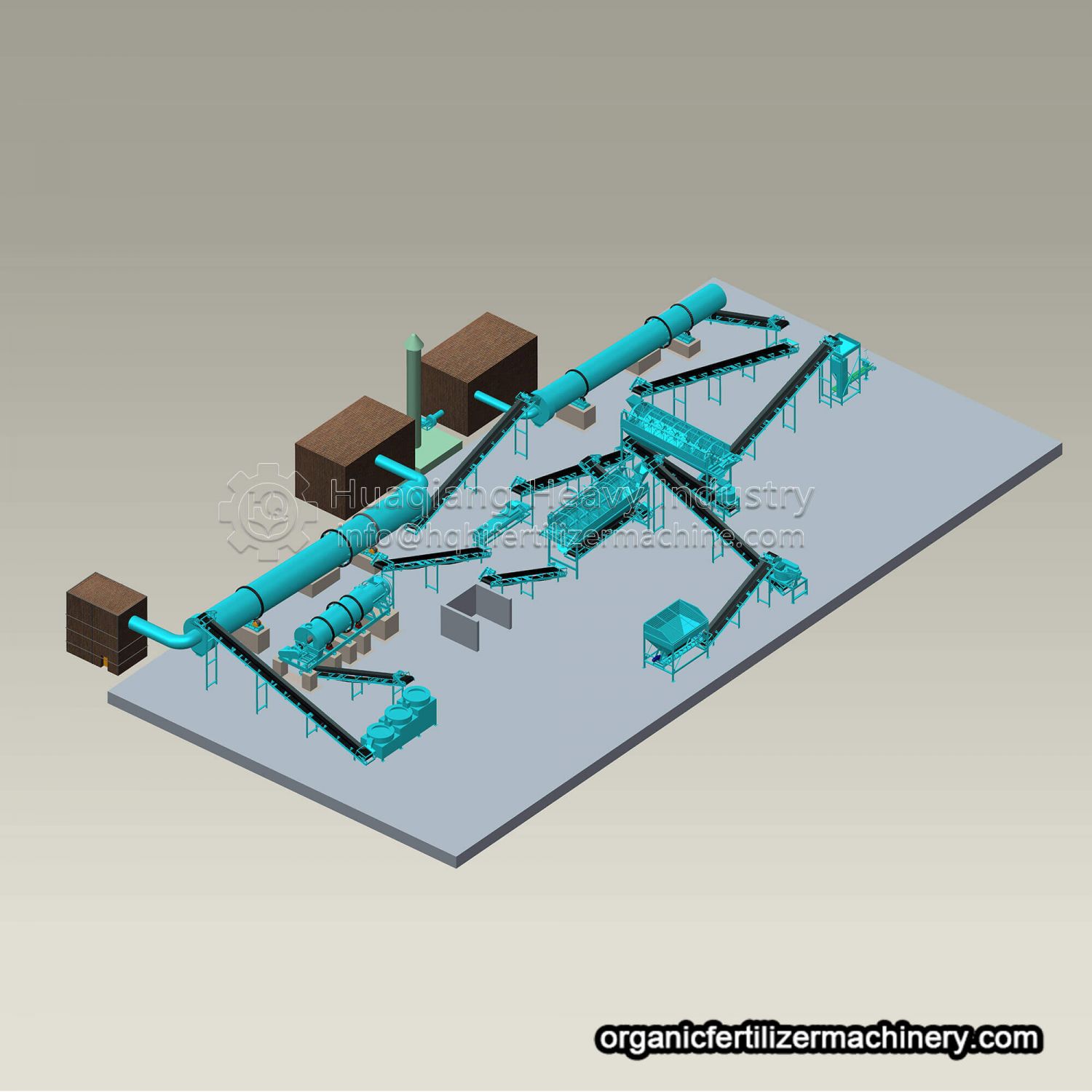

Producing the organic fertilizer granulator using the fertilizer manufacturing technology is easier to operate and the fertilizer engineers designed a series of fertilizer production line to make the different type fertilizer.Like the

organic fertilizer manufacturing proccess is designed for producing the organic fertilizer granulator.More type,like the bio fertilizer production.In the fertilizer production line,it equipped with different type and different series fertilizer machines.In the organic fertilizer production line,the new type organic fertilizer granulator,which the fertilizer granulator machine is designed for producing the organic fertilizer granulator.

We are as the fertilizer machine manufacturers,we are not only design and produce the fertilizer machines,we also design complete fertilizer production lines for different type raw materials and different type producing requirement.More fertilizer producing method that ou want to know more,you can visit our website and leave a message for us,we will apply to you as soon as possible.