The selection of organic fertilizer production line equipment directly determines production efficiency, product quality, and overall costs. It requires a comprehensive consideration of multiple factors to avoid blind investment. The following are the core elements influencing equipment selection, providing a reference for production enterprises.

Raw material characteristics are the primary prerequisite for equipment selection. Different raw materials have significantly different physical and chemical properties, requiring highly specific equipment compatibility. If the raw materials are livestock and poultry manure, straw, or other fibrous materials, high-efficiency crushing equipment, such as a semi-wet material crusher, should be prioritized, along with a fermentation turning machine to ensure sufficient decomposition of the raw materials. If the raw materials have a high moisture content (over 60%), dewatering equipment, such as a screw press dewatering machine, is needed to reduce the difficulty of subsequent processing. In addition, the particle size and impurity content of the raw materials will also affect equipment selection; raw materials with high impurity content require screening equipment to prevent equipment wear.

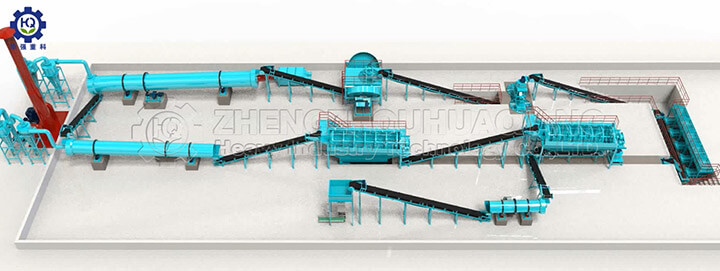

Production scale determines equipment specifications and capacity configuration. Small-scale production (daily output below 50 tons) can use small, integrated equipment, balancing flexibility and low cost, such as small compost turning machines and disc granulators, without the need for complex supporting facilities. Medium-to-large-scale production (daily output above 100 tons) requires a complete set of highly automated equipment, including large fermentation tanks, drum rotary granulators, drying and cooling machines, and automatic packaging lines, to improve production efficiency and reduce labor costs. At the same time, space should be reserved for equipment expansion to accommodate future capacity increases.

Product positioning influences equipment function selection. Organic fertilizers for different uses have different requirements for particle size, purity, and nutrient content, which directly determine the equipment combination. Producing commercial organic fertilizers requires meeting market standards, necessitating precise batching equipment, granulation equipment, and screening equipment to ensure uniform particles and low impurity content. Producing organic fertilizers for self-use can simplify the process and reduce investment in fine processing equipment. Furthermore, if biological organic fertilizer is to be produced, additional equipment for microbial inoculation and constant-temperature fermentation is required to ensure microbial activity.

Cost budget and operating costs need to be comprehensively considered. Equipment procurement costs should match the company's financial strength, avoiding excessive pursuit of high-end equipment that could lead to cash flow pressure. At the same time, energy consumption, consumable costs, and maintenance costs of the equipment must be considered. Choosing equipment with low energy consumption and easy maintenance can reduce long-term operating costs.

Policy requirements and site conditions should also not be overlooked. Environmental policies have clear regulations on dust and exhaust emissions from organic fertilizer production, requiring the installation of dust removal and deodorization equipment to avoid environmental violations; the site area determines the equipment layout. Narrow sites require the selection of vertical equipment with a small footprint, while spacious sites can accommodate horizontal complete sets of equipment to optimize the production process.

In summary, the selection of organic fertilizer production equipment should be based on the characteristics of the raw materials, combined with production scale, product positioning, cost budget, and policy and site conditions. It is also crucial to choose a fertilizer machinery manufacturer with comprehensive process design capabilities to ensure the stability and compatibility of the equipment and maximize production efficiency.