Double roller granulator is a kind of molding machine which processes materials into specific shapes. It is extruded by die or rolled into granules and packed directly in bags. It is widely used in chemical, petrochemical, pharmaceutical, food, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics and other fields.

Technology of double roller granulator

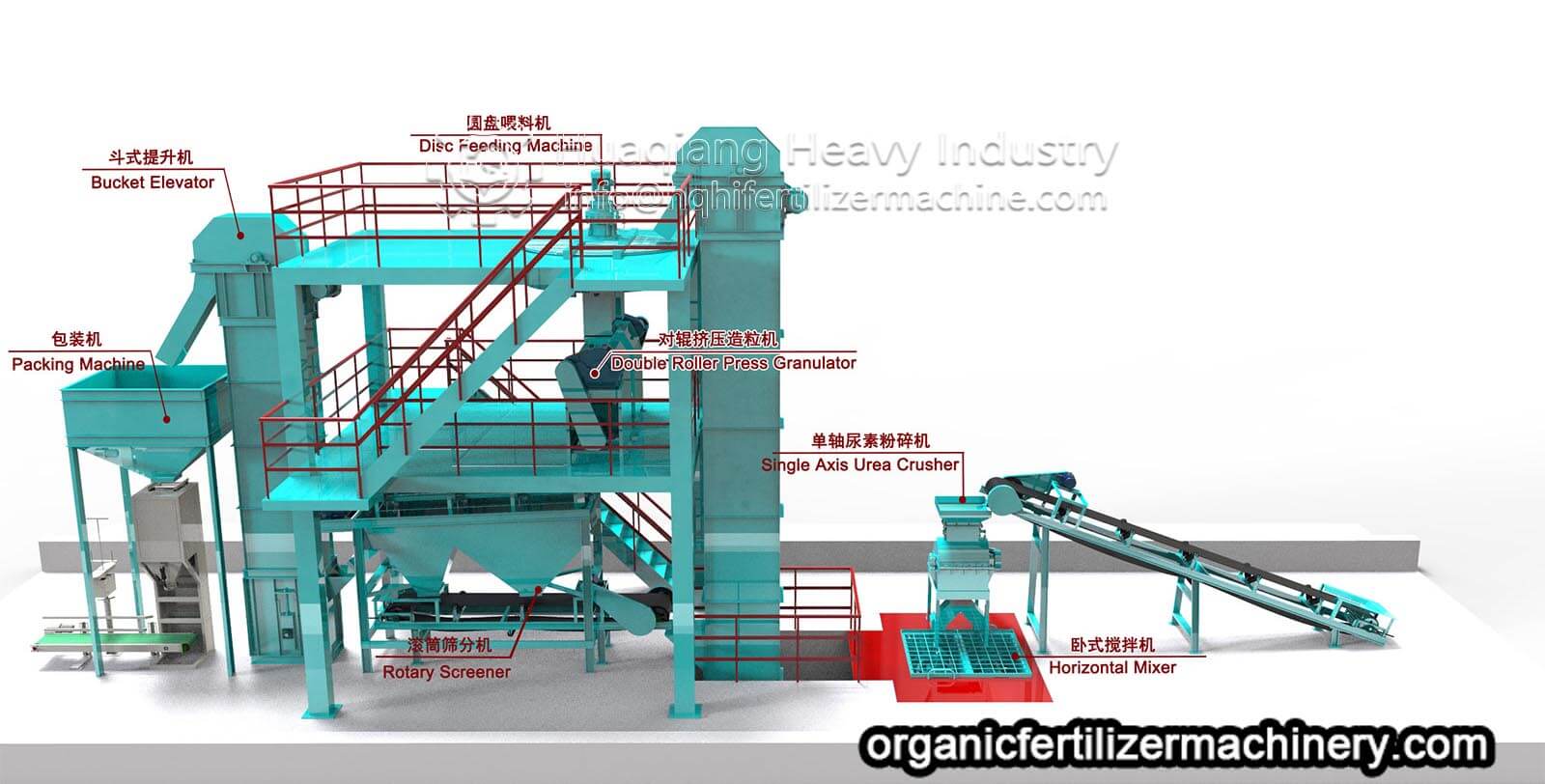

Automatic batching → mixing and mixing → uniform feeder → double roller granulator → screening → packaging.

The material selection and pretreatment of the double roller granulator are strict and should be adjusted to the appropriate moisture content. The

fertilizer granulation machine also requires fine texture and good bonding.

Its characteristics are as follows: the process is simple, the drying process can be omitted; the product has high water content, thick columnar particles, good granulation, uniform particle size, but easy to collapse during storage and transportation; low production capacity, high relative power, stable quality, but the equipment is easy to wear.

My company produces fertilizer granulation machine has disc granulator, npk fertilizer granulator, double roller granulator, organic fertilizer granulator machine, drum granulator, flat die pelleting machine, and ring die pelleting machine.

Fertilizer granulator machine price concessions, stable operation, convenient maintenance, quality assurance, the majority of users like!