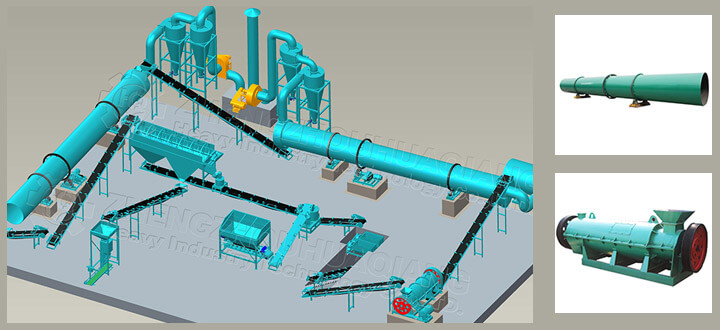

The use of organic fertilizer equipment to produce organic fertilizers in the industry has become a trend. Organic fertilizer plays an important role in improving soil and improving fruit tree yield and quality. Organic fertilizer can be produced by using various organic materials, animal manure, stacking manure, green manure, straw, mixed fertilizer and humic acid. The main equipment of organic fertilizer production line is introduced below.

Compost turning machine

In the production of organic fertilizer, pig manure, cattle, sheep, horses, chickens, ducks and other livestock manure, sludge waste and sugar mill sludge should be treated in a harmless manner by trough fermentation. The organic fertilizer turning machine will ferment these wastes to increase the air circulation during the fermentation of the materials. The compost turner can be continuously discharged or batched, high in efficiency and stable in operation.

Organic fertilizer crushing equipment

The half-wet material crusher is used to crush fermented materials, so that the crushing granularity of compost can meet the granulation requirements. The crushing equipment can adjust the crushing granularity within a certain range according to the needs of users. The moisture content of organic fertilizer material can reach 25-50% by half-wet material crusher machine.

Mixer

The stirring shaft of mixer rotates continuously under the drive of the motor, and the material rolls continuously under the swing of the positive and negative two groups of blades on the stirring shaft, so that the material is fully stirred uniformly. The blades of the mixer are made of alloy material, which has high wear resistance and strong impact resistance, which greatly prolongs the maintenance period.

Granulation equipment for organic fertilizer production line

Rotary dryer, cooler equipment

The rotary dryer is mainly used for drying wet granules after granulation of organic fertilizer. The equipment can also be used to dry other materials. The shape of the dryer machine is a low-speed rotating drum installed at a certain inclination. The inside of the cylinder has a lifting device for lifting a metal plate. The dryer device is driven by a motor through a speed reducer to drive a pair of sprockets, so that the large sprocket or the large ring gear fixed to the cylinder rotates. Our company produces drying equipment suitable for various raw materials, pig manure dryer, chicken manure dryer, duck manure dryer.

The cooler machine is a kind of equipment for cooling materials in large quantities. In the organic fertilizer production line, it rotates continuously to make the material roll and exchange heat with the air. At the same time, as the cooling machine rotates according to the design inclination and rotation speed, the organic fertilizer particles are The inlet is delivered to the discharge end.

Drum screening machine

The drum screening machine is used for grading products, so that the finished products are evenly classified, and the separation of finished products and returned materials is simple in structure and convenient in operation, and is an indispensable device in the organic fertilizer production line.