For organic fertilizer,granulation is an indispensable process link in the production of organic fertilizer.At present,there are many models of equipment for granulator machine of organic fertilizer.Through the models of

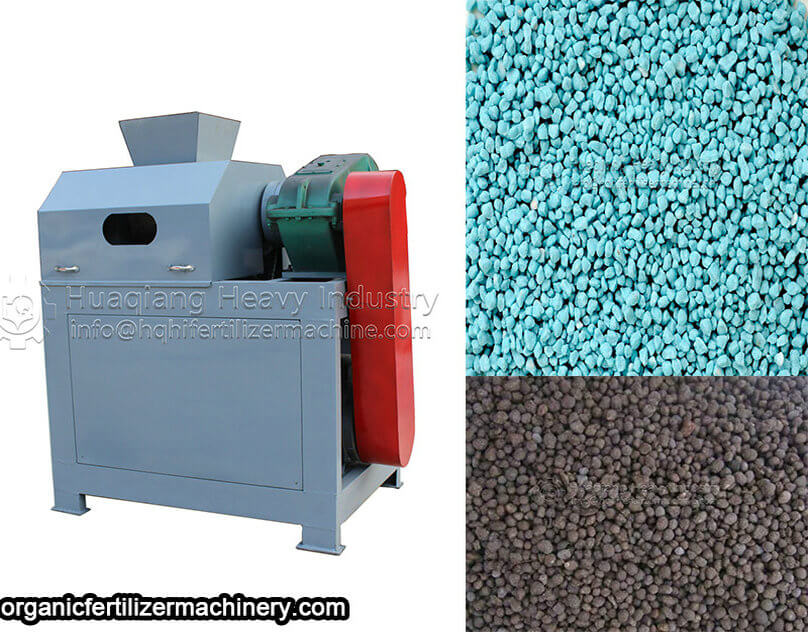

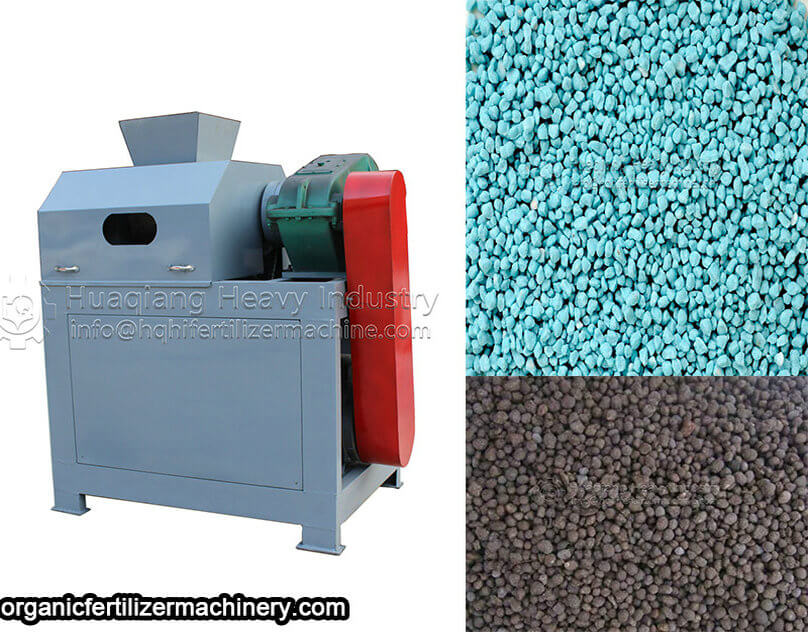

fertilizer granulator machine,there are many differences between the disc granulator machine and the opposite roller press granulator machine due to the differnces in granulating production technology,which makes the users have great differences in the selection of these two models.Today,there are professional.The organic fertilizer machine manufacturer will give you a detailed disclosure of which is more suitable for organic fertilizer granulation.For example,disc granulator and roll extrusion granulator.

From the perspective of production process,the two kinds of disc granulators have afvantages over the opposite roll extrusion granulator.From the perspective of production process,the processing technology of disc granulator and opposite roll extrusion granulator are not too complex.For example,the difference between the two equipment in the granulation appearance process is that the particle size of the disc granulator has high degree of freedom,good smoothness and roundness,and the particle size of the

roller press granulator is relatively uniform.But there are some defects in the appearance.However,it can be made up by the organic fertilizer rounding machine.

However,from a professional point of view,they are quite different.They cannot make up for each other.As we all know,organic manure is made of animal manure through deep processing of prfessional organic fertilizer machine.It is mainly composed of organic fertilizer matter,with poor conditions for cellulosic polymorphosis,adding live bacteria with fertilizer making function,and the production process should not be exposed to high temperature.It's not suitable to adopt material making methods.Because of these two processes,the raw materials are required to have high crushing fineness,high granulating water content and generally about 30% water content.Therefore,the drying load is large,the effective bacteria loss is large,and the pelletilizing rate is low(about 60%-70%),the dust is very large during the

fertilizer manufacturing process and the operating environment is very poor.Therefore,for the production of organic biological fertilizer,the crushing,high molding rate(more than 95%),low moisture content of particles after opening,small drying load,which can reduce the loss of effective bacteria,small dust and good operating environment.