The advantages of

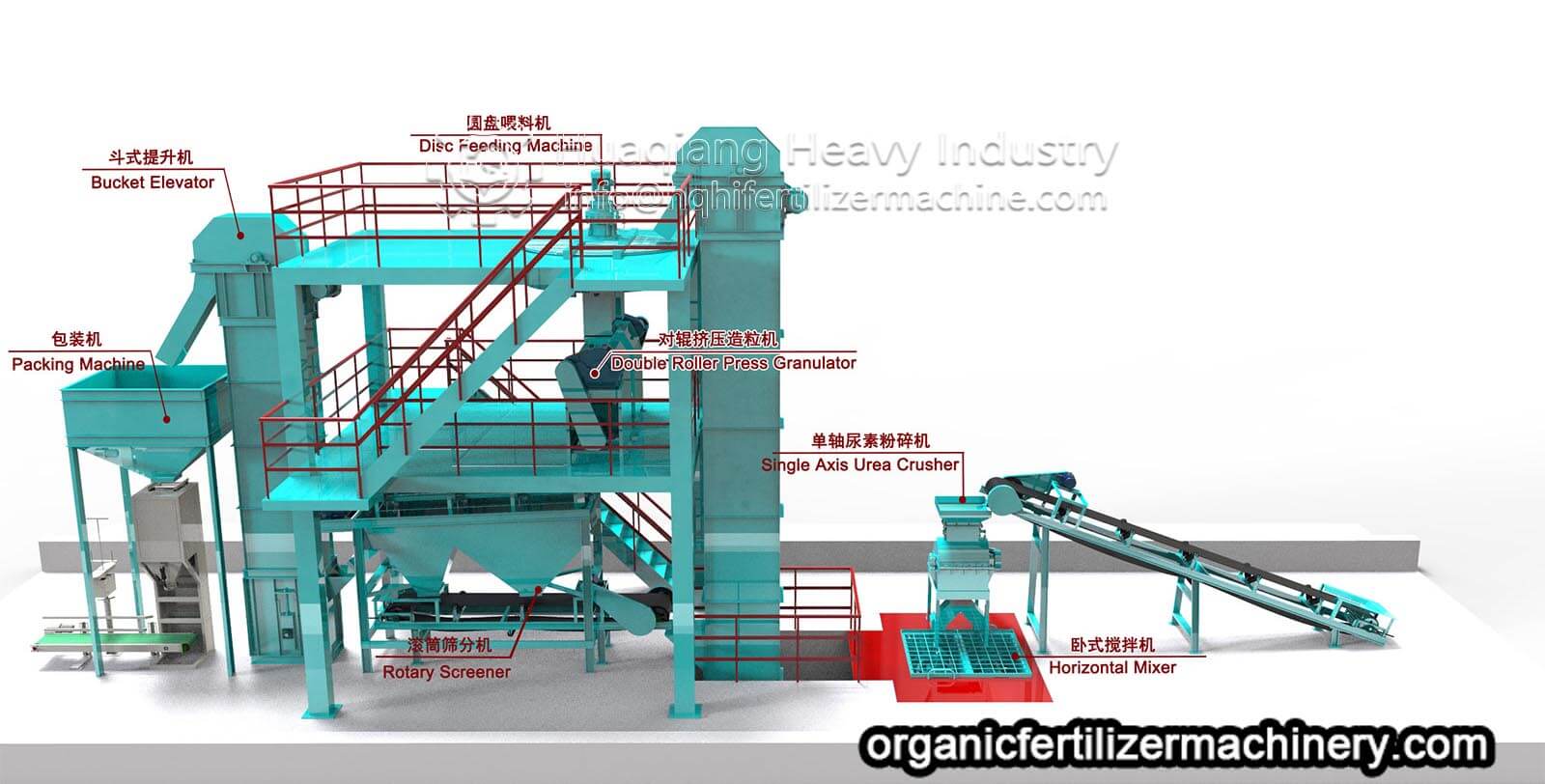

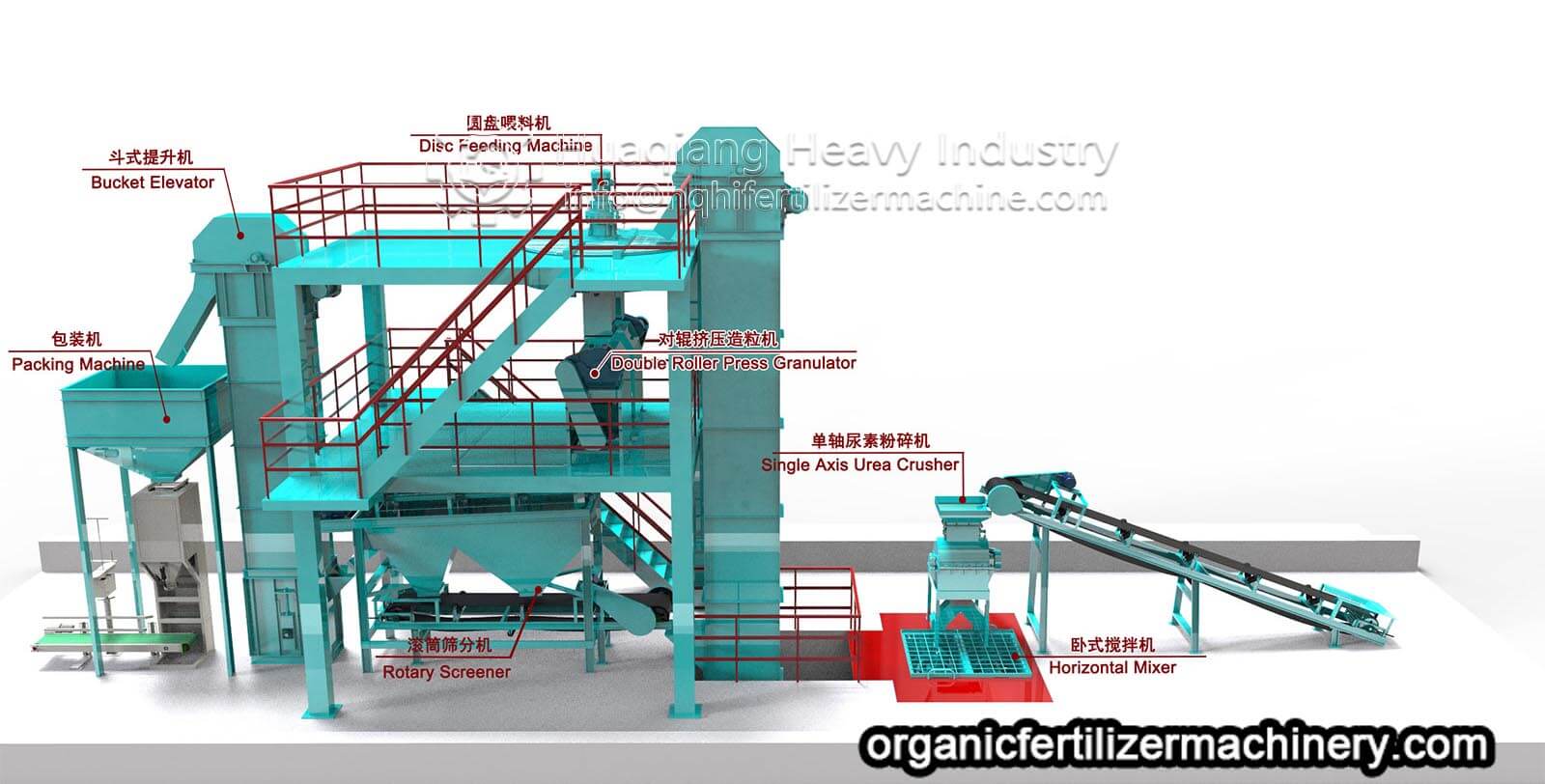

double roller granulator in the production technology of compound fertilizer are energy saving and consumption reduction. Extrusion fertilizer is made by materials at room temperature. Compared with other methods, it does not need monotonous methods such as fuel oil and gas. There is no need to add other binders. Steam granulation is commonly used to produce compound fertilizer in China. Water vapor condenses and crystallizes between the molecules of materials, and then acts as a binder in the process of manufacturing. But in the monotonous process, it is necessary to drive out the water inside and outside the fertilizer, otherwise the fertilizer is easy to bond and caking in the storage process. The dry process does not need other additives, but only uses the intermolecular force of the material itself, which simplifies the process and reduces energy consumption.

The investment of double roll granulator is low, because the monotonous process is saved, the return ratio is low (about 15% of the total feed volume of kneading machine), the technical process is simple and the investment is low. The material group of NPK fertilizer granulator survived. At that time, there were more than 20 kinds of materials successfully used in extrusion granulation: urea, ammonium chloride, potassium chloride, potassium sulfate, etc. In addition, the use of extrusion granulation technology can complete the conversion of commodity formula in a very short time, and a set of equipment can produce more than 30 kinds of commodity formula.

Usage: since all parts of the new

fertilizer granulation machine have not been run in, it is necessary to raise the temperature of the equipment when it is started. Generally, it takes 0-50 minutes. For specific operation, first raise the temperature to the point where you can pull the motor V-belt freely.