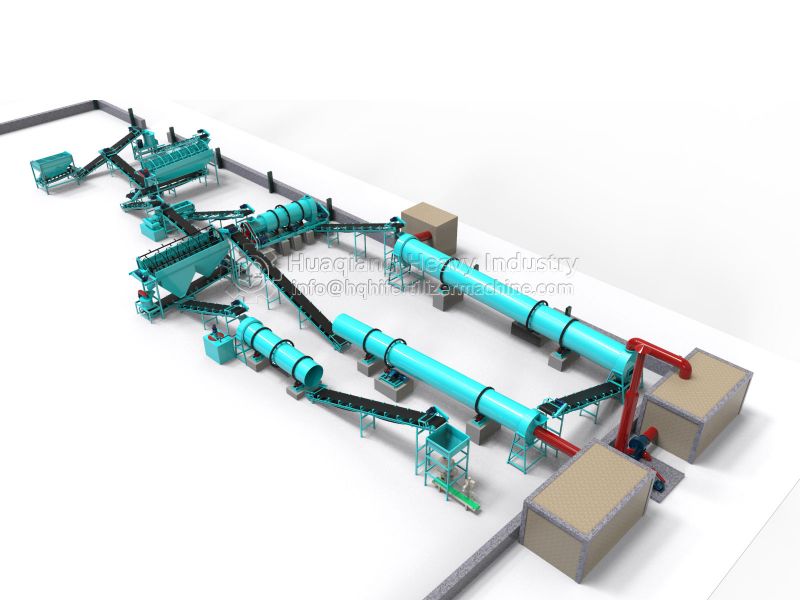

The organic fertilizer production line utilizes organic waste such as livestock and poultry manure, crop straw, and mushroom residue as core raw materials. Supported by professional organic fertilizer production equipment, it transforms waste into valuable resources through standardized and regulated processes. The core process follows a closed-loop system of "pretreatment—fermentation—deep processing—finished product," balancing environmental protection and harmlessness with the maximization of nutrient retention. It is adaptable to various finished product forms, including powder and granules, and is a crucial support for the green development of modern agriculture.

Raw material pretreatment is the foundation of production and directly affects subsequent fermentation efficiency and fertilizer quality. First, qualified raw materials are selected, and impurities such as stones and plastics are removed to prevent damage to the organic fertilizer machinery or affecting the purity of the finished product. The materials are then transported to the processing workshop via conveying equipment. A crusher is used to crush coarse fiber materials such as straw and branches to less than 2 cm, significantly increasing the contact area for microorganisms and improving the fermentation rate. Subsequently, the material moisture content is precisely adjusted to 55%-65%, and carbon source additives such as rice husks and sawdust, and nitrogen source additives such as urea are added. The carbon-nitrogen ratio is strictly controlled between 25:1 and 30:1. A special compound fermentation agent is then added and thoroughly mixed using a mixer to ensure full contact between the agent and the materials, laying a solid foundation for the subsequent fermentation process.

Aerobic fermentation is the core process, directly determining the maturity and safety of the fertilizer. The uniformly mixed materials are stacked using a pile or trough fermentation process. A compost turning machine is used to regularly turn the piles, ensuring sufficient oxygen supply during fermentation and achieving even heat dissipation, preventing localized high or low temperatures from affecting the fermentation effect. Temperature is monitored in real time during fermentation, maintaining a high temperature of 55-70℃ for 7-10 days to thoroughly kill insect eggs, pathogens, and weed seeds in the materials, reducing the risk of use in farmland. The fermentation cycle is usually 15-25 days. After fermentation, the material is transferred to a curing warehouse for 10-15 days to complete the medium-low temperature post-ripening process, stabilizing the organic matter and eliminating the risk of secondary fermentation after fertilizer application.

The deep processing stage is flexibly adjusted according to the type of finished product to meet different agricultural production needs. During the production of powdered organic fertilizer, the aged materials are crushed and finely sieved again. Materials meeting the standard fineness are directly sent to the packaging stage, while the coarser materials are returned to the crushing process for recycling, improving raw material utilization. The production of granular organic fertilizer requires three additional key processes: granulation, drying, and cooling. First, the powdered base material is precisely formulated with nutrients and then processed into granules using a disc or new type organic fertilizer granulator. The granules are then dried to a moisture content of less than 15% to prevent mold during storage. After cooling to room temperature, they are sieved again. Unqualified granules are crushed and returned for re-granulation, ensuring uniform and high-quality finished granules.

Finished product packaging and testing are the final stages. Automatic packaging machines weigh, bag, and seal the product, while simultaneous sampling and testing of organic matter content and heavy metal indicators ensure compliance with industry standards. The entire process prioritizes environmental protection, incorporating odor control and wastewater treatment facilities to achieve the resource utilization of organic waste. This not only solves pollution problems but also provides high-quality organic fertilizer for farmland, contributing to improved soil fertility and sustainable agricultural development.