Powdered organic fertilizer is made from livestock manure, crop straw, and other agricultural waste, after harmless treatment. The organic fertilizer production line has a simple process and moderate investment, suitable for small and medium-scale production. The equipment configuration revolves around four main stages: pre-treatment, fermentation, deep processing, and packaging. The core organic fertilizer machines each perform their specific functions, ensuring product quality and production efficiency.

Pre-treatment equipment is fundamental to production, and includes crushers, screening machines, and mixers. The crusher type should be selected based on the raw material characteristics; hammer crushers are suitable for dry, loose straw, while double-shaft crushers are suitable for high-moisture manure. The raw materials are crushed to 2-5 cm to increase the contact area for microorganisms. The screening machine removes impurities such as stones and plastics, preventing damage to subsequent equipment; the mixer blends the raw materials in the correct proportions, controlling the carbon-nitrogen ratio and moisture content, creating optimal conditions for fermentation and decomposition.

Fermentation equipment is a core component, and a compost turning machine is indispensable. It achieves full contact between the material and oxygen through regular turning, promoting microbial metabolism and heat generation, ensuring complete decomposition of the material and killing pathogens and insect eggs. Small-scale operations can use windrow compost turning machines for greater mobility; medium-to-large scale operations are better suited to large-wheel compost turning machines, which are more efficient and suitable for fermentation tank operations.

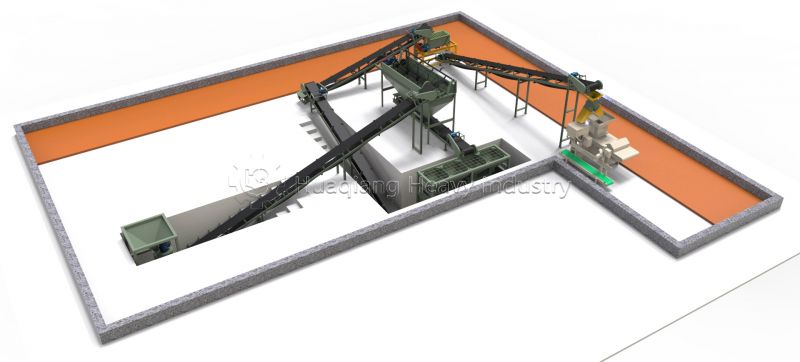

Deep processing and auxiliary equipment determine the precision of the finished product and the continuity of production. A fine crusher grinds the decomposed material to 20-40 mesh, ensuring uniform particle size; a finished product screening machine screens the qualified powder, removing any undigested large pieces. Conveyors are responsible for material transfer between each stage, and packaging machines can be selected as semi-automatic or fully automatic models as needed, achieving quantitative weighing and sealing. Dust removal equipment is also required to handle dust generated during crushing and screening, meeting environmental protection requirements.

The entire set of powdered organic fertilizer production equipment offers flexible investment options. A small-scale production line can be equipped for 50,000-100,000 RMB. The equipment structure is simple and easy to maintain. Compared to granular organic fertilizer production lines, it eliminates the need for granulation and drying equipment, significantly reducing investment and operating costs. This makes it suitable for small and medium-sized investors and rural agricultural recycling projects, contributing to the resource utilization of agricultural waste and achieving both ecological and economic benefits.