With the development of ecological agriculture, the demand for organic fertilizers is increasing, making the purchase of suitable organic fertilizer production equipment a crucial decision for many farmers, livestock cooperatives, and organic fertilizer plants. The rationality of equipment selection directly impacts production efficiency, product quality, and return on investment. Therefore, the following key issues must be carefully considered when purchasing organic fertilizer equipment.

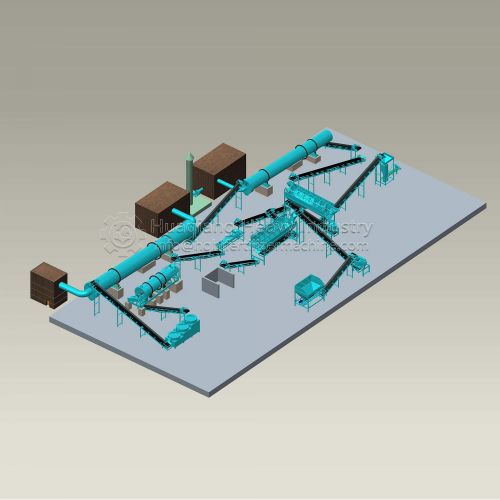

First, clearly defining production needs is paramount. Equipment should be selected based on the type of raw materials (such as livestock manure, crop straw, kitchen waste, etc.), planned production capacity, and product form (granular fertilizer, powder fertilizer, columnar fertilizer). For example, processing high-moisture manure requires priority in equipping fermentation and turning equipment, while producing granular fertilizer requires a complete set of equipment including granulators and dryers. If the planned production capacity is too small, it may not meet market demand; if it is too large, it will lead to equipment idenness and energy waste.

Secondly, equipment quality and performance are crucial. High-quality organic fertilizer machine should have stable operation, high material conversion rate, and low failure rate. Attention should be paid to the materials of the core components of the equipment, such as the knife shaft of the turning machine and the molds of the granulator; high-quality materials can extend the service life of the equipment. At the same time, prioritizing equipment with a high degree of automation can reduce labor input and improve production efficiency, especially suitable for large-scale production.

Thirdly, costs and benefits need to be accurately calculated. In addition to the equipment purchase cost, subsequent energy consumption, maintenance costs, and spare parts supply must also be considered. Some low-priced equipment may have low initial investment, but high energy consumption and are prone to damage, and long-term maintenance costs may far exceed expectations. It is recommended to choose a fertilizer machinery manufacturer with high cost-effectiveness and comprehensive after-sales service to ensure that equipment failures can be repaired promptly, avoiding delays in production.

Finally, environmental protection and compliance cannot be ignored. Current environmental requirements are becoming increasingly stringent, and equipment must meet local environmental standards and have corresponding capabilities for treating exhaust gas, wastewater, and solid waste. For example, the odor generated during the fermentation process requires odor removal equipment to avoid environmental pollution. At the same time, it is necessary to confirm that the equipment manufacturer has relevant qualifications and that the products have passed quality certification to ensure that the production process is legal and compliant.

In summary, purchasing organic fertilizer equipment is a systematic project that requires comprehensive consideration of production needs, equipment quality, cost-effectiveness, and environmental compliance. Thorough research and comparing different options are essential to choosing the most suitable equipment, laying a solid foundation for organic fertilizer production and achieving a win-win situation in both ecological and economic benefits.