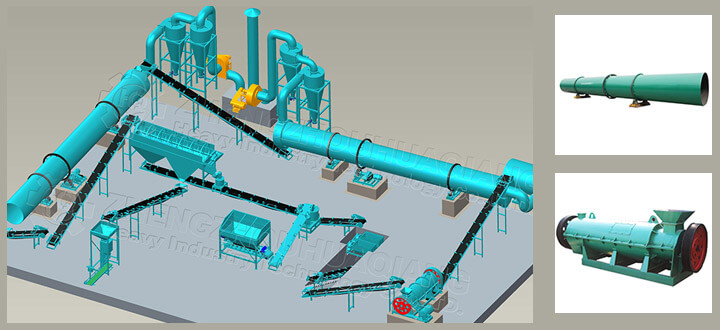

With the concept of green agricultural development gaining widespread acceptance, organic fertilizers replacing chemical fertilizers have become an important measure to promote ecological agriculture. A complete set of organic fertilizer production line equipment is the core support for realizing the resource utilization of organic waste and the large-scale production of organic fertilizers. Many people are confused about the composition of a complete set of equipment. In fact, it is a complete system of equipment covering raw material processing, fermentation and composting, deep processing, and finished product packaging. The equipment in each link works collaboratively, and none of them can be omitted.

Raw material pretreatment equipment is the starting point of the organic fertilizer production line, mainly responsible for processing raw materials such as livestock and poultry manure, straw, and wood chips into qualified fermentation substrates. The core equipment includes a half-wet material crusher, which can efficiently process pre-fermentation raw materials with a moisture content of less than 30%, achieving a crushing fineness of 20-30 mesh, meeting the needs of subsequent processes; and a solid-liquid separator, which can reduce the moisture content of high-moisture manure to 60%-65%, and the separated liquid can be further processed into liquid fertilizer. In addition, the feeding conveyor is responsible for the automated transportation of raw materials, reducing manual handling costs.

Fermentation and composting equipment is crucial for organic fertilizer production, determining product quality. The complete set of equipment usually includes a compost turning machine, which comes in trough type, crawler type, etc., and can regularly turn the materials, replenish oxygen, and control the fermentation temperature at 55-70℃, shortening the fermentation cycle to 7-10 days; coupled with an electrical automatic control system, it can achieve fully automatic and intelligent operation of the fermentation process.

Deep processing equipment mainly realizes the transformation from composted materials to finished organic fertilizer, covering multiple sub-systems. The crusher further refines the composted materials; the horizontal mixer in the mixing system ensures uniform mixing of raw materials with extremely low residue; the granulation system can choose a disc granulator, a new type organic fertilizer granulator, etc., according to needs, with a granulation rate of over 95% and uniform particle size.

Subsequent processing and packaging equipment ensures the quality of the finished product and convenient storage and transportation. The drum dryer and cooler in the drying and cooling system reduce the moisture content of the granules to below the standard level, enhancing granule strength; the drum screening machine separates qualified and unqualified granules, with unqualified granules being returned to the crushing stage for reuse; finally, an electronic quantitative packaging scale and automatic sewing machine complete the weighing, bagging, and sealing of the finished product.

In addition, the complete set of equipment also includes auxiliary systems such as dust removal and conveying, ensuring efficient and environmentally friendly production. The equipment configuration can be flexibly adjusted for different scales of organic fertilizer production lines, but the core equipment system remains consistent. This set of organic fertilizer production equipment not only achieves the harmless and resource-efficient treatment of organic waste but also promotes the large-scale and standardized development of the organic fertilizer industry, injecting lasting momentum into ecological agriculture.