The stable operation of an organic fertilizer production line is crucial for ensuring production capacity and product quality, and is directly related to production safety and environmental compliance. During actual operation, the following key issues must be addressed to ensure efficient, safe, and environmentally friendly operation of the production line.

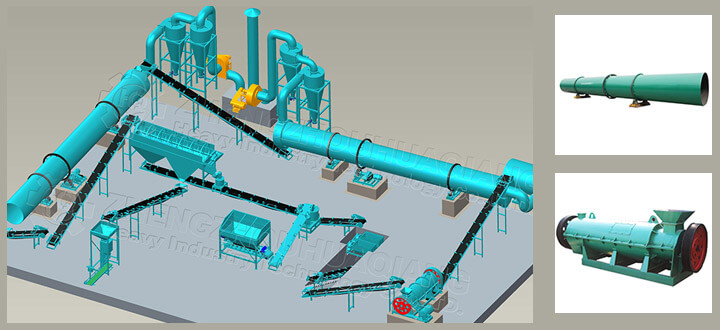

Equipment pre-inspection and daily maintenance are fundamental. Before starting the equipment, a comprehensive inspection of the pulverizer, mixer, granulator, dryer, and other organic fertilizer machine must be performed to confirm sufficient bearing lubrication, secure transmission component connections, and intact protective devices. During operation, monitor equipment temperature, vibration, and abnormal noises in real time, and immediately stop the equipment for troubleshooting if any abnormalities are detected. After each day's production, residual materials in the equipment must be cleaned to prevent clogging, and vulnerable parts should be regularly replaced and maintained to extend the service life of the organic fertilizer production equipment.

Raw material control and process parameter management are key to ensuring product quality. Raw materials must be strictly screened to remove impurities such as stones and metals, preventing damage to the equipment and affecting fertilizer purity. Based on indicators such as raw material moisture content and organic matter content, precisely adjust process parameters such as mixing ratio, granulation speed, and drying temperature—the drying temperature is generally controlled at 60-80℃ to ensure that the moisture content meets the standards without destroying nutrients. At the same time, ensure uniform material transport in each process to avoid blockages and interruptions, maintaining a stable production rhythm.

Safety protection and standardized operation cannot be ignored. Operators must be certified and wear protective masks, gloves, and other personal protective equipment. Unauthorized operation of equipment is strictly prohibited. The production line area must have clear safety warning signs, and unauthorized personnel are strictly prohibited from entering. In addition, regularly inspect electrical circuits and fire-fighting facilities to ensure electrical safety and prevent fire hazards.

Environmental compliance is the bottom line of production. Dust generated during the production process must be effectively collected through equipment such as pulse dust collectors to prevent air pollution; fermentation wastewater must be treated to meet discharge standards to prevent soil and water pollution. At the same time, properly dispose of production waste to achieve both resource recycling and environmental compliance.

In short, the operation of an organic fertilizer production line requires attention to equipment maintenance, process control, safety protection, and environmental management. Only through scientific and standardized management and operation can the synergistic improvement of production capacity, quality, safety, and environmental protection be achieved.