In the wave of green agricultural development, organic fertilizers are highly favored for their dual value of soil enrichment and environmental protection. Efficient production relies on a complete set of professional organic fertilizer production equipment. Organic fertilizer production involves four core stages: raw material pretreatment, fermentation, processing and shaping, and finished product packaging. Each stage has its own dedicated equipment, collectively forming a standardized production chain.

The raw material pretreatment stage is the foundation of quality control, with the core equipment including crushers and mixers. Crushers can crush large raw materials such as straw and oilseed cakes to 5-10mm, increasing the surface area of the material to improve fermentation efficiency. half-wet material crushers are specifically designed for high-humidity raw materials such as livestock and poultry manure, providing excellent crushing results. Mixers, through special structures such as double spirals, uniformly mix livestock and poultry manure, straw powder, and fermentation agents in proportion, ensuring balanced nutrients and adjusting the carbon-nitrogen ratio to a suitable range for fermentation.

The fermentation stage is the core of organic fertilizer production line, and the compost turning machine is the key equipment in this stage. Common trough-type compost turning machines are suitable for large-scale production, achieving thorough turning through track movement; windrow compost turning machines are highly flexible and suitable for outdoor stacking scenarios; hydraulic compost turning machines, with their deep turning capabilities, can turn materials from 30-80cm deep to the surface, ensuring aerobic fermentation and significantly shortening the fermentation cycle. Closed fermentation tanks further improve fermentation efficiency and environmental protection through precise temperature and humidity control.

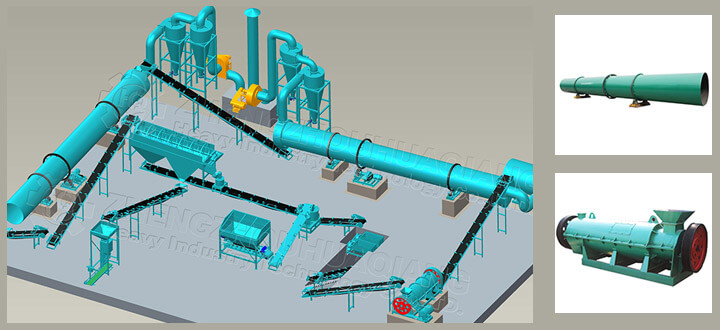

Processing, shaping, and finished product packaging equipment determine the marketability of the product. Granulators are available in various types, including disc and drum types. Disc granulators are suitable for small-scale production, while rotary drum granulators have a large capacity and are suitable for large-scale needs. After granulation, a drum dryer reduces the moisture content to below 15%, followed by a cooler to prevent caking. A drum screener machine then separates unqualified particles. Finally, an automatic quantitative packaging machine completes precise weighing and sealing, and a coding machine completes product labeling, enabling efficient factory output.

These organic fertilizer machines work together to address the pain points of low efficiency and unstable quality in traditional organic fertilizer production, and also promote the resource utilization of agricultural waste. With technological advancements, intelligent and energy-efficient equipment is constantly emerging, providing a solid guarantee for the high-quality development of the organic fertilizer industry.