In agricultural production,it is often necessayr to use chicken manure organic fertilizer to fertilizer crops.The production line of chicken manure organic fertilizer is a special production line of this kind of fertilizer.What knowledge do we have about chicken manure organic fertilizer production line?

Organic fertilizer machine of chicken manure organic fertilizer production line:

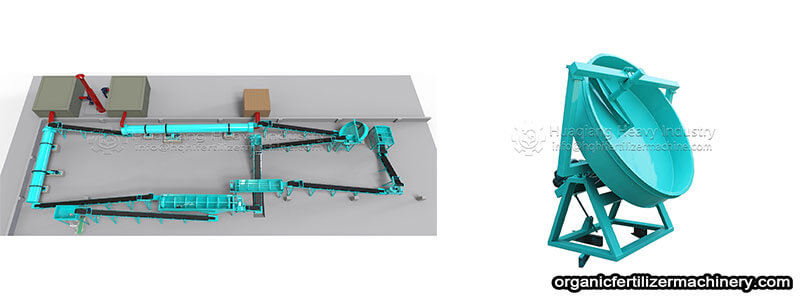

There are two steps for the production line of chicken manure organic fertilizer to process commerical organic fertilizer;the part of early fermentation and treatment and the part of deep processing granulation.The supporting equipment of bio organic fertilizer equipment needs fermenting and throwing machine,organic fertilizer crusher,roller screener machine,horizontal mixer machine,disc granulator machine which this type fertilizer granulator machine is to be designed for producing the organic fertilizer granulator,rotary dryer,cooler machine,screener machine,coating machine,packaging machine,conveyor and other organic fertilizer machine.The heavy industry chicken manure organic fertilizer production line is a complet set of production equipment which takes fresh chicken manure as raw material and produces natural organic chicken manure fertilizer after a series of processing.

In the

fertilizer manufacturing process,it is to be equipped with different type and series fertilizer ,what characteristics of chicken manure organic fertilizer production line:

1.Chicken manure organic fertilizer does not contain any chemical components.Due to the poor digestion ability of chicken,only 25% of the nutrients can be consumed,while the other 75% of the nutrients in feed are discharged with the manure,so that the dry product contains nitrogen,phosphorus,potassium,organic matter,amino acid,protein and other components.

2.The main substance of chicken manure organic fertilizer is organic matter,which increase the content of organic matter in soil.Organic matter can improve the physical,chemical and biological characteristics of soil,ripen the soil and improve the soil fertility.To some extent,the proverb"the ground is raised by manure,and the seedings grow by manure"in rural areas of China reflects the effect of chicken manure organic fertilizer on soil improvement.

3.Chicken manure organic fertilizer not only increases a lot of organic colloids, but also decomposes many organic matters into organic colloids with the help of microorganisms, which greatly increases the adsorption surface of soil, and produces a lot of sticky substances, which makes soil particles cemented into stable aggregate structure, improves the performance of soil water conservation, fertilizer conservation and air permeability, and regulates the ability of soil temperature .

4.Chicken manure organic fertilizer can also make a large number of microorganisms in the soil,especially many benefical microorganisms,such as nitrogen fixing bacteria,ammoniating bacteria,cellylose decomposting bacteria,nitrifying bacteria etc.There are various active enzymes secreted by the digestive tract of animals and produced by microorganisms in chicken manure organic fertilizer.When these substances are applied to the soil,they can greatly improve the enzyme activity of the soil.

5. More application of chicken manure organic fertilizer can improve the soil activity and biological reproduction and transformation ability, thus improving the absorption, buffering and stress resistance of soil.

In the fertilizer manufacturing process,the production line of chicken manure organic fertilizer adopts the first floor layout,which reduces the capital construction investment and facilitates the operation and control.Bucket elevator is not used in the transportation equipment of chicken manure organic fertilizer production line.Although the bucket elevator has beautiful shape and small floor area,it is easy to damage the particles,and it is easy to block,difficult to clean,high failure rate and large space occuption.

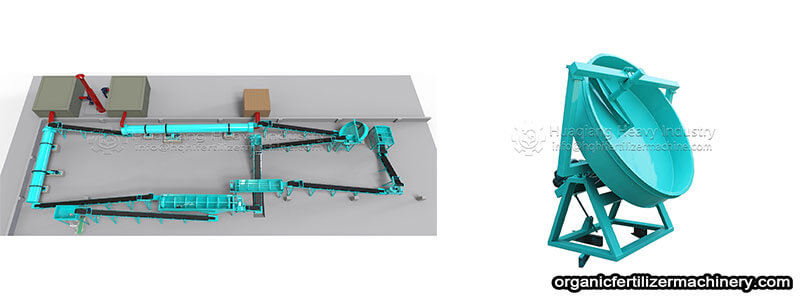

The belt convyor and large conveyor are all selected for the conveying equipment of this process,which not only ensures the smoothness of the conveying system,protects the particles,reduces te height of the plant and reduces the captial construction investment.The way of pelleting is disc granulator,which this type

fertilizer granulator machine has wide adaptability to raw materials,large output and improve the appearance quality of products.