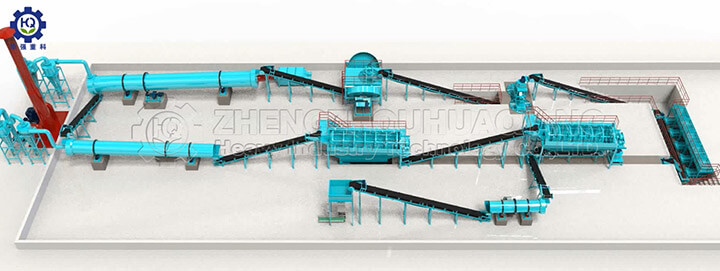

The stable operation of an organic fertilizer production line is crucial for ensuring production capacity and product quality. Scientific and standardized maintenance can extend the service life of organic fertilizer production equipment, reduce downtime due to malfunctions, and lower maintenance costs. Based on the core processes of crushing, fermentation, granulation, drying, and screening, comprehensive maintenance work should be carried out throughout the entire production line.

Daily maintenance is fundamental and should be implemented before starting and after stopping the equipment each day. Before starting, check that all equipment connection bolts are tightened and that the tension of conveyor belts and chains is appropriate to prevent loosening or detachment during operation. Clean residual materials from the equipment's inlet and outlet to prevent clogging, especially cleaning the granulation machine's die holes and the screening machine's screens. Also, check the lubricating oil level and hydraulic oil pressure, and replenish any missing oil to ensure sufficient lubrication of the transmission parts.

Regular maintenance should be carried out systematically based on the equipment's operating time, focusing on inspecting easily worn parts. Crushing equipment requires monthly inspection of the hammerheads and liners for wear, and timely replacement of severely worn parts to prevent the crushed particle size from being substandard; the fermentation turning machine requires quarterly inspection of the turning teeth and gearbox, cleaning of humus attached to the machine body, and checking for aging of seals. Granulation and drying equipment should undergo a comprehensive disassembly and inspection every six months, cleaning accumulated material on the inner wall of the drying drum, repairing the granulation mold, and replacing aging seals and bearings.

Specialized maintenance should be tailored to the material characteristics and equipment operating conditions. Organic fertilizer materials contain moisture and humus, which are corrosive to equipment. Therefore, metal parts need regular rust removal and anti-corrosion treatment, applying anti-rust paint or anti-corrosion coatings. The electrical control system should be protected from dust and moisture, and the insulation of the wiring should be checked regularly. Dust should be cleaned from the control cabinet to prevent short circuits. In addition, instruments should be calibrated regularly to ensure accurate display of parameters such as temperature, pressure, and speed.

Maintenance work should be recorded in a logbook, documenting equipment operating time, maintenance content, and replaced parts for easy traceability and troubleshooting. Furthermore, operators must follow standard operating procedures to avoid improper operation that could exacerbate equipment wear. Scientific maintenance is not just about maintaining a single component, but rather a comprehensive and ongoing management process. Only by implementing it thoroughly can the organic fertilizer production line operate continuously and efficiently, thus safeguarding large-scale production.