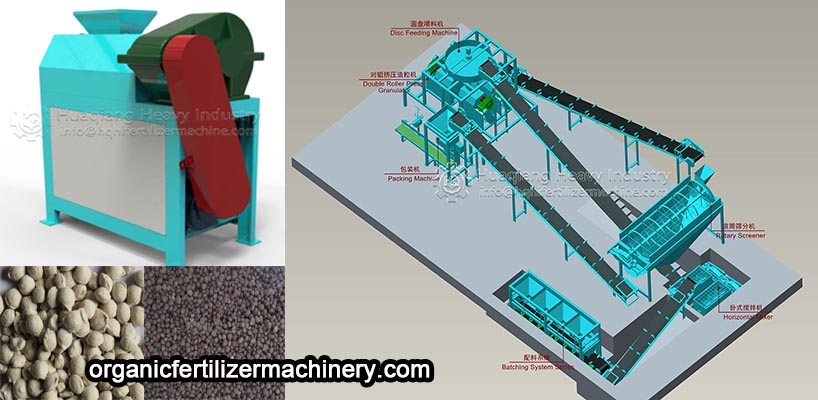

Brief introduction of compound fertilizer extrusion granulation process

1) The qualified raw materials are added into the high-efficiency mixer according to the ratio requirements and mixed evenly.

2) It is transported to the disc feeder to remove the iron substance in the material during the conveying process.

3) The material in the disc feeder evenly enters the

double roller granulator, and the material is forced to pass between the two rollers to be extruded into a thin sheet. The thin sheet is crushed into fragments by the coarse crusher under the roller for screening, and the material on the screen continues to be crushed and screened.

4) The semi-finished products are transported to the finished product screening machine, and the screened fine particles are directly returned to the disc feeder, while the large particles are crushed by the crusher and then returned to the disc feeder.

5) The qualified products after screening are transported to the automatic packaging scale for weighing, packaging and warehousing.

The advantages and disadvantages of compound fertilizer produced by extrusion granulation process are as follows

a) Extrusion granulation does not need to heat and humidify the material, which not only saves investment and energy, but also can adapt to the granulation of heat sensitive materials, such as ammonium bicarbonate and some organic fertilizers.

b) There is no waste water or waste gas discharged in the production process, which will not pollute the environment.

c) Extrusion granulation process is short, easy to operate, easy to realize automatic control of production and improve production efficiency.

d) There are no special requirements for the properties and particle size distribution of raw materials, so the sources of raw materials are wide.

e) The production of the

fertilizer granulation machine is flexible, and the product scheme can be changed at any time, which is conducive to small batch production of special fertilizer.

f) The particle size distribution of the product is uniform, without segregation and caking.

g) The shape of extrusion granulation product is not as round as that produced by drum granulation, slurry granulation and other traditional methods; if chemical reaction occurs between ingredients in product particles, it may lead to particle disintegration.