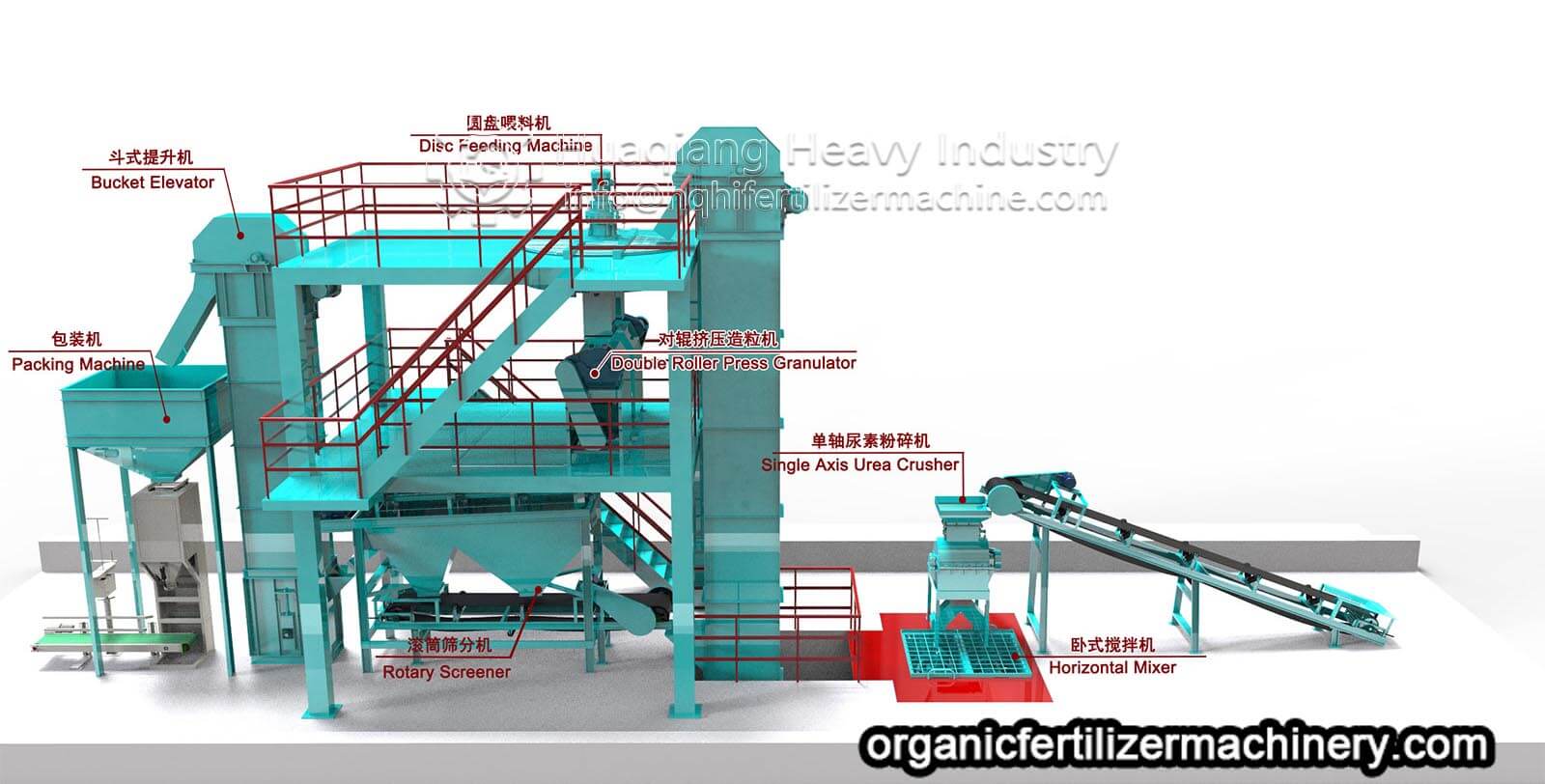

No drying extrusion granulation production line is composed of horizontal mixer,

double roller granulator, disc feeder, screening machine, finished product silo, packaging machine and belt conveyor. The investment of production line is about 60000-200000 yuan according to the automation degree of output. The complete set of equipment of double roller granulator has the advantages of compact and reasonable layout, low investment, low energy consumption, small occupation area and high output.

The working principle of the double roller granulator is that the horizontal mixer first mixes and mixes various raw materials according to the proportion. After the materials are evenly mixed, the materials are transported to the disc feeder by the belt conveyor. The disc feeder uniformly sends the materials to the double roller granulator for granulation through the mixing movement. After granulation, the belt conveyor transports the finished products to the drum screening machine for screening, and the finished products directly enter the silo The powder is transported back to the inside of the conveyor and returned to the

fertilizer granulation machine.

The head accessories of the double roller granulator, such as the price of the roll skin of the double axis extrusion granulator, the main shaft of the double axis extrusion granulator, the debugging disk, the gear, the bearing, the bearing seat, the eccentric sleeve, the oil seal and other accessories, the crushing of the opposite roller granulator (Langya stick), the screen of the extrusion granulator.

A variety of materials, such as alloy steel, stainless steel roll skin, sanluo 13 and other roller skin materials, are selected for the roller skin of the double roller granulator. After a series of processes, such as high temperature forging, mechanical processing, drilling and milling rod, the finished product is then subjected to high temperature quenching. After these processes, the roller skin of the double roll extrusion granulator is wear-resistant, corrosion-resistant and has a long service life.