Granulation is the core process of an organic fertilizer production line, directly determining the product's forming rate, strength, and application effect. In actual production, the following key points must be carefully controlled to ensure stable operation of the production line and the production of high-quality products.

Raw material pretreatment is the foundation for successful granulation. First, the moisture content of the raw materials must be controlled. Excessive moisture content can easily lead to granule sticking and clumping, while insufficient moisture content makes granulation difficult. This can be adjusted by drying or spraying with water. Simultaneously, ensuring uniform particle size is crucial; pulverization is recommended to avoid large particles affecting the granulation effect. Furthermore, the carbon-to-nitrogen ratio and pH value of the raw materials must be properly adjusted, and harmful substances should be removed through pre-fermentation to prevent secondary fermentation during granulation.

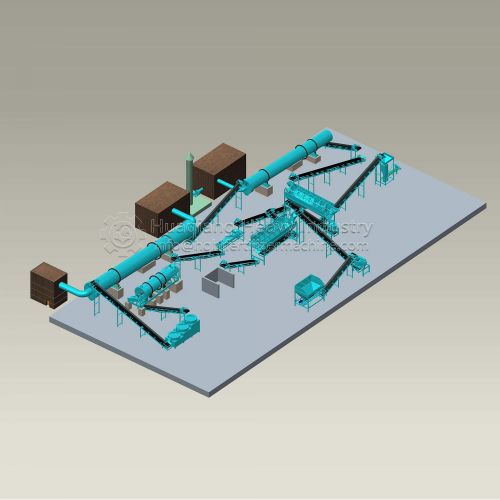

Equipment debugging and operational procedures are indispensable. As the core equipment of an organic fertilizer production line, before starting the organic fertilizer granulation machine, key parameters such as drum speed, scraper angle, and die orifice size must be checked. During operation, residual materials on the inner walls of the equipment should be cleaned regularly to prevent adhesion and maintain particle uniformity. Good lubrication of the transmission system is also crucial to prevent production interruptions due to mechanical failure. Throughout the process, the coordinated operation of other organic fertilizer machines on the production line must be monitored to avoid single-equipment problems affecting overall efficiency.

Dynamic control of process parameters is key. Granulation temperature must be maintained within a suitable range; excessively high temperatures will destroy beneficial microorganisms in the organic fertilizer, while excessively low temperatures will affect particle strength. The amount of binder should be adjusted according to the characteristics of the raw materials; commonly used binders include straw powder and bentonite, but excessive use should be avoided to prevent reduced fertilizer efficiency. Particle size needs to be adjusted according to market demand; unqualified particles should be separated using a screening device and returned to the granulator for reprocessing.

Quality monitoring and safety/environmental protection must be implemented simultaneously. Particle forming rate, compressive strength, and moisture content should be monitored in real time, and parameters should be adjusted promptly upon detection of abnormalities. Dust collection is essential during production to prevent pollution from airborne organic materials. Wastewater must be properly treated to ensure compliance with environmental emission standards. Operators must wear protective equipment and strictly adhere to equipment operating procedures to prevent mechanical injuries and dust hazards.

In summary, the organic fertilizer granulation process needs to take into account multiple factors such as raw materials, equipment, technology, and safety, and achieve a dual improvement in product quality and production efficiency through scientific management and control.