The organic fertilizer equipment for livestock and poultry manure needs to be equipped with fermentation tossing machine, disc granulator, horizontal mixer, roller screening machine, semi wet material grinder, cooler, dryer, coating machine, automatic quantitative packaging machine and other equipment. The cow dung organic fertilizer equipment produced by our company is advanced in technology, energy saving and consumption reduction, reliable in operation, stable in operation, compact in process layout, scientific and reasonable, no three emissions, convenient in maintenance, and wide in raw material adaptability.

Pollution of livestock and poultry feces to soil: livestock and poultry farmers usually directly apply livestock and poultry feces to the farmland for the purpose of waste utilization. However, since the feces contain a large amount of sodium and potassium salts, the increase of sodium and potassium elements will damage the soil structure and lead to the decrease of soil permeability. In addition, livestock and poultry feed contains some metal trace elements, which are not absorbed by livestock and poultry and will be directly excreted through feces. If they act on farmland, they will seriously damage the soil and affect the output of the land.

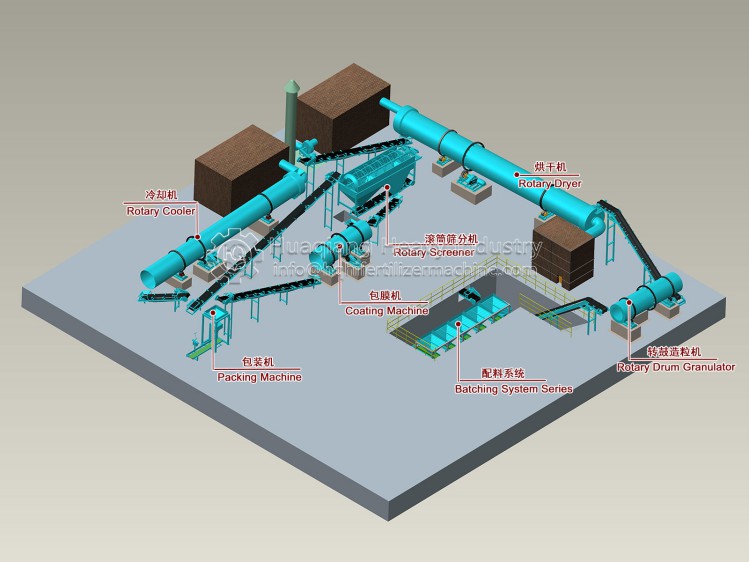

There are many kinds of organic fertilizer production equipment, but the main difference is the difference in function and output. Let's take a look at what a complete organic fertilizer production equipment includes. Commonly used equipment includes:

Fermentation tipping machine: the fermentation tipping machine is also divided into tank type tipping machine and self-propelled tipping machine. It is mainly used for the fermentation of raw materials, deodorization and sterilization, and plays the role of complete maturity.

Organic fertilizer pulverizer: Vertical Pulverizer and semi wet material pulverizer are commonly used to pulverize fermented raw materials. The finer the pulverization, the higher the success rate of the production, and the fuller and more beautiful the particles.

Forklift feeding bin: for the uninterrupted feeding of production, the role of the feeding bin is to temporarily store materials and then connect them to the production line for feeding. It is divided into ordinary feeding machine and symmetrical feeding machine.

Organic fertilizer mixer: vertical mixer and horizontal mixer are common. They are mainly used for mixing raw materials and auxiliary materials to make organic matter more evenly distributed. When adding trace elements such as nitrogen, phosphorus, potassium, etc., fully stir to make the materials more uniform, which is suitable for the mixing of common organic fertilizer materials.