The high-temperature oxygen consuming organic fertilizer fermentation tank is a complete set of equipment for professional treatment of livestock and poultry feces, kitchen waste, domestic sludge and other organic wastes. Through high-temperature aerobic fermentation, the activity of microorganisms is utilized to biodegrade and decompose the organic matter in the waste, so that the organic waste can be finally converted into organic fertilizer for soil improvement, landscaping, and realizing the resource utilization of organic waste.

The fermentation tank is mainly composed of fermentation chamber, hydraulic power system, main shaft drive system, feeding lifting system, automatic high-pressure air supply system, discharge system, deodorization system and automatic control system. During operation, the material is first sent to the fermentation chamber by the feeding lifting system, and the hydraulic power system is turned on. The main shaft starts to rotate to realize material mixing. At the same time, the air supply system and auxiliary heating system are turned on to maintain the microbial fermentation conditions. After the materials are decomposed and stabilized under the action of microbial agents, the hydraulic power system is used to open the blanking valve, and the belt conveyor is used to output the fermented materials. The gas discharged after fermentation is collected and treated by the deodorization system and discharged after reaching the standard.

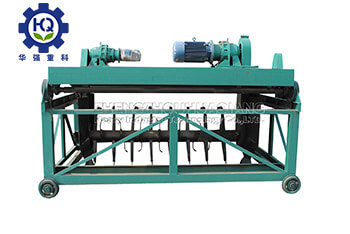

Bar type fermentation equipment. Generally, the equipment required for strip stack fermentation is a self-propelled stacker. The self-propelled stacker has the advantages of flexibility, simplicity, large processing capacity and good air permeability. However, it is necessary to leave enough space between stacks, and at the same time, the materials must have a certain stacking angle, so the floor area is large. At present, the large-scale self-propelled organic fertilizer dumper is mainly imported, and the price is not cheap. All of them adopt hydraulic transmission mode and have the characteristics of engineering machinery. There are also small and medium-sized self-propelled stacker in China, with low price. The equipment produced by some large enterprises has certain reliability.

Compared with the traditional compost fermentation, the use of organic manure fermentation tank to ferment livestock and poultry manure has the following advantages: small footprint, high automation, and one person can complete the whole fermentation process; Through the deodorization system, the gas can be discharged up to standard without secondary pollution; The main body of the equipment is made of stainless steel, which reduces corrosion and has a long service life; Main body thermal insulation design and auxiliary heating ensure normal operation of equipment in low temperature environment. The use of fermentation tank to ferment livestock and poultry manure has the following disadvantages: large investment in organic fertilizer equipment, high energy consumption and high operating cost; Because the traditional compost is greatly affected by the external temperature, the production efficiency of the organic compost fermentation tank is lower in the warm season and higher in the cold season compared with the traditional compost.