When purchasing organic fertilizer equipment for pig manure processing, it is necessary to first determine the output size of the organic fertilizer equipment. It can be calculated based on annual production or monthly production. Secondly, it is necessary to determine the shape of the finished product. Organic fertilizers can be made into powder, spherical particles, cylindrical shapes, and flat spherical shapes. The different shapes of particles result in different granulator equipment used. The materials produced by the disc granulator, the rotating strand granulator, and the stirring tooth granulator are spherical; The organic fertilizer produced by the roller extrusion granulator is flat spherical, and there are various types of granulators for you to choose from.

Firstly, there are pig manure organic fertilizer fermentation equipment, which are commonly referred to in the industry as flipping machines, flipping machines, and pig manure organic fertilizer fermentation microbial agents. The fermented pig manure organic fertilizer is transported by forklift to the semi-finished product warehouse, and then onto the pig manure organic fertilizer equipment for fully automated assembly line production.

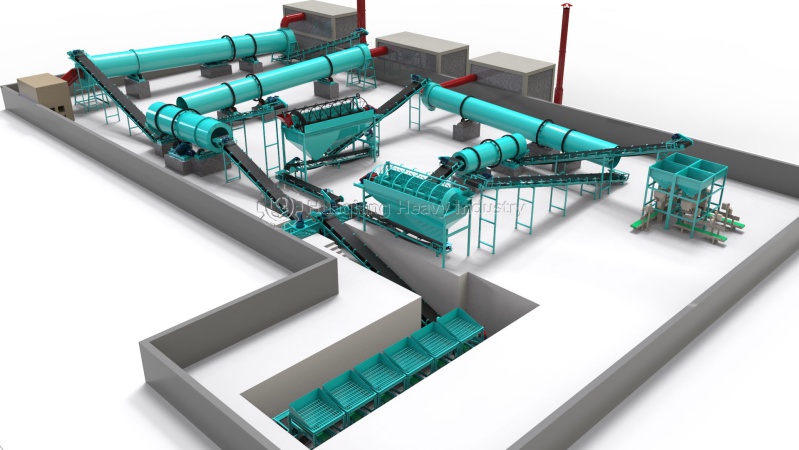

The pig manure organic fertilizer equipment includes crushing process, screening process, granulation process, drying, cooling process, particle screening process, and finally to the packaging process, which is connected by a belt conveyor. Nowadays, there are a large number of pig farming enterprises in various regions, and as a result, pig manure resources are also very abundant. Utilizing this large amount of pig manure to produce organic fertilizer solves the major problem of environmental pollution, while also producing a large amount of pig manure organic fertilizer. The economic benefits are also very considerable.

Pig manure organic fertilizer equipment processing technology fully automated production equipment, easy to operate, can start insulation devices and oxygen supply systems according to needs, create a suitable environment for bacterial growth, fast speed. The pig manure organic fertilizer processing equipment also uses aerobic fermentation, fully utilizes fermentation heat, and the fermentation cycle only takes 5-7 days. The fermentation process is not affected by seasonal climate, operates all day, and the feces are processed on the same day, which can be installed in the breeding farm, The daily processing capacity is 360 cubic meters, and the annual production capacity is 50000 tons. The organic fertilizer produced using pig manure organic fertilizer equipment not only creates economic benefits for enterprises, but also makes significant contributions to human environmental protection projects.