Correct use and maintenance of the whole set of organic fertilizer equipment

Organic fertilizer equipment is generally made of steel, which is easy to rust if it is wet for a long time. Most people will put the organic fertilizer equipment in the set position as usual. When it is sunny and rainy, they will find that some parts of the equipment are rusty and some mechanical parts are aging for a long time. How to avoid rusting of organic fertilizer equipment in rainy season?

First of all, prevent iron parts from rusting. Most parts of the organic fertilizer equipment are made of iron. If stored improperly, it is easy to rust and shorten the service life. The preventive measures are to disassemble, apply anti-rust paint and store in a dry and ventilated place for drying.

The second is to prevent the aging of rubber parts. If the rubber parts are affected by moisture or oil, it is easy to age and crack, and shorten the service life.

The next step is to prevent the motor from getting damp. If the motor is not used for a long time, it should be placed in a ventilated, dry and clean room. If the motor is placed in a wet place or is easy to be soaked by rain, the motor will be affected by moisture, which may lead to the reduction of insulation performance, short circuit, electric leakage, iron striking, and even coil burning, that is, click to burn the coil.

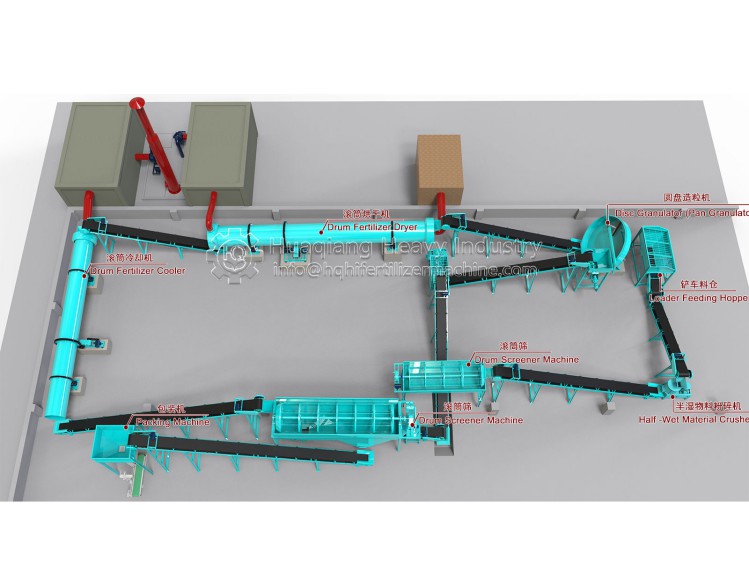

How To Use an Organic Fertilizer Production Equipment

More and more farmers are looking for ways to produce organic fertilizer as the organic movement continues to grow. While there are many commercial products available, some farmers are choosing to make their own fertilizer using organic production equipment.

There are a few things to keep in mind when using organic fertilizer production equipment. First, it is important to choose the right equipment for your needs. There are a variety of organic fertilizer production systems available, so it is important to select the one that best fits your operation.

Second, it is important to follow the manufacturer’s instructions when using the equipment. This will ensure that you are using the equipment properly and that you are getting the best results.

Finally, it is important to monitor the organic fertilizer production process carefully. This will help you troubleshoot any problems that may arise and make sure that the fertilizer is being produced correctly.