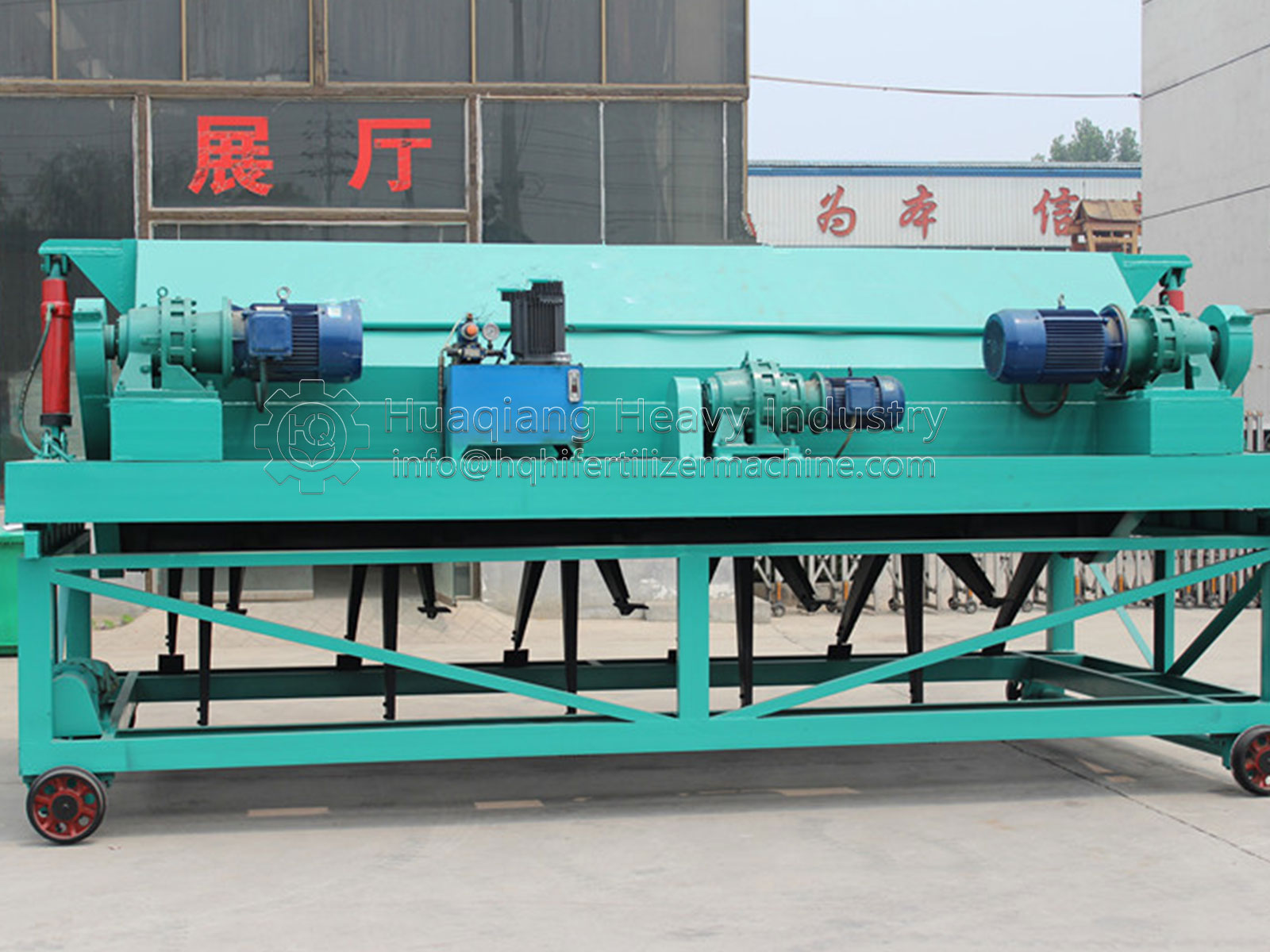

The tank type organic fertilizer turning and throwing machine is a kind of turning and throwing equipment matched with the fermentation tank. Rails are installed on the top of both sides of the fermentation tank, and the tipping machine can run back and forth on the rails. The general tank type flip flop is equipped with one machine and multiple tanks. The transfer of the flip flop between the fermentation tanks can be realized by the transfer machine. The trough type organic fertilizer throwing machine is mainly composed of a frame, a throwing device, a traveling mechanism, a cable reel device and an electric control system, and is mainly driven by electric power. The tank type fermentation system has the advantages of small space occupation, high composting depth, fast temperature rise and large processing capacity. The tank type flip flop is widely used in China and is the main flip flop equipment for livestock and poultry manure composting in China. It can be divided into gear shifting type, chain plate type and spiral type according to the different throwing devices.

The traveling mechanism of the trough type organic fertilizer dumping machine is generally arranged with four steel wheels. The reduction motor transmits power to the steel wheel through chain transmission, or the main shaft of the reduction motor is directly connected with the drive axle for power transmission. The driving forms are double motor drive and single motor drive, and the single motor drive is divided into one side wheel drive and two side wheel drive. When the single motor single side wheel drive is started, the rotation speed of the wheels on both sides is inconsistent, which may lead to direction deflection or vibration, and even the whole machine may overturn, affecting the operation safety. Double side wheel drive of single motor can make the wheels on both sides run synchronously. However, in the case of large-span transmission, the two wheel shafts and the transmission shaft have different shafts, which reduces the power transmission efficiency and produces vibration during operation, affecting the stability of operation. Double motor drive can avoid these disadvantages that affect the stability and safety of operation. Double motor drive mode should be adopted for the trough type tipping machine. During operation, the smaller the working forward speed of the whole machine, the better the effect of dumping and mixing. However, the production efficiency of the operation shall also be considered, which shall not be greater than the length of the material pile that can be dumped in the forward direction of the equipment. The power and production capacity of the tipping machine are mainly determined by the working forward speed, tipping width and tipping height. In the complete set of equipment for organic fertilizer processing, the production capacity shall match the processing capacity of the equipment before and after the process, and the utilization rate of the equipment shall be considered.