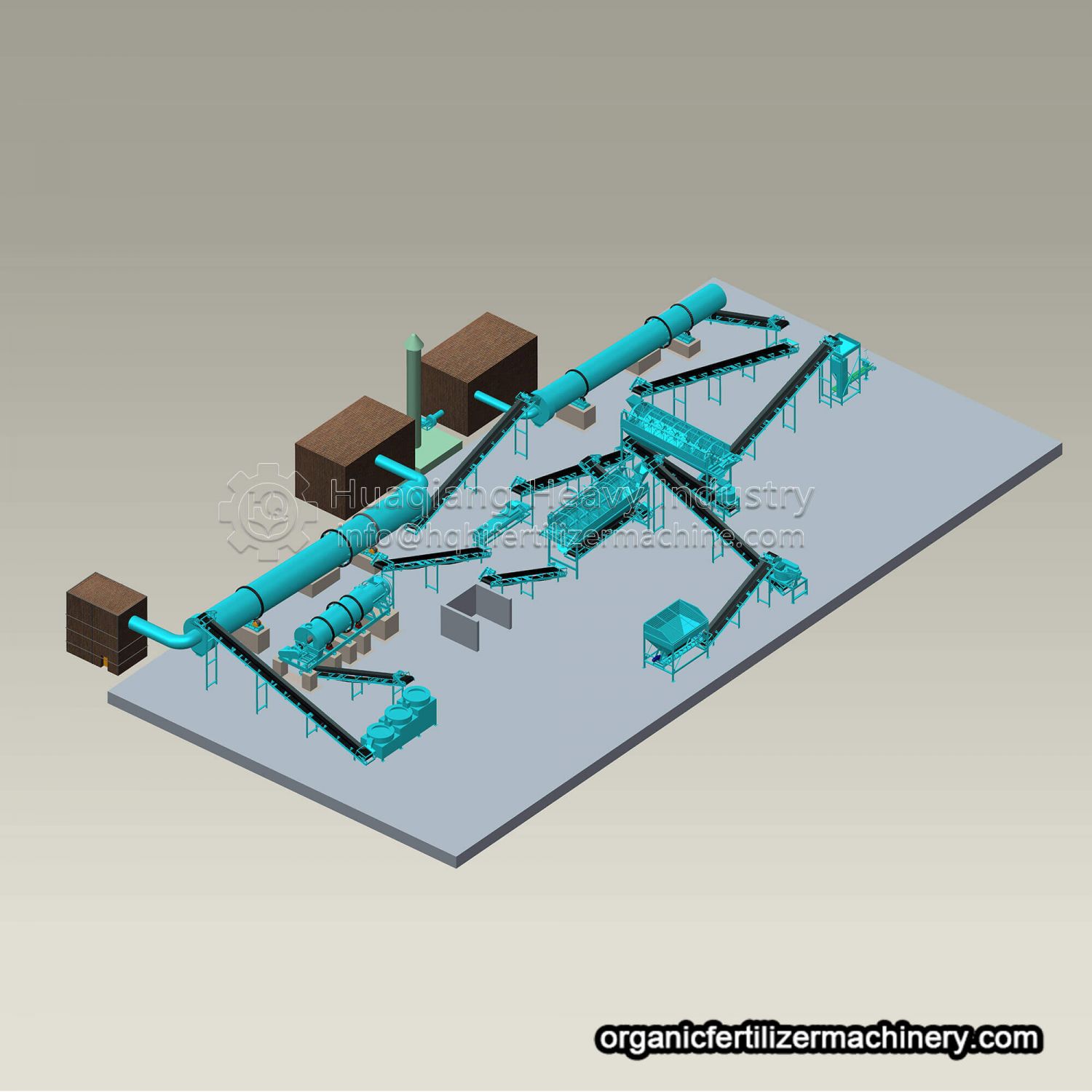

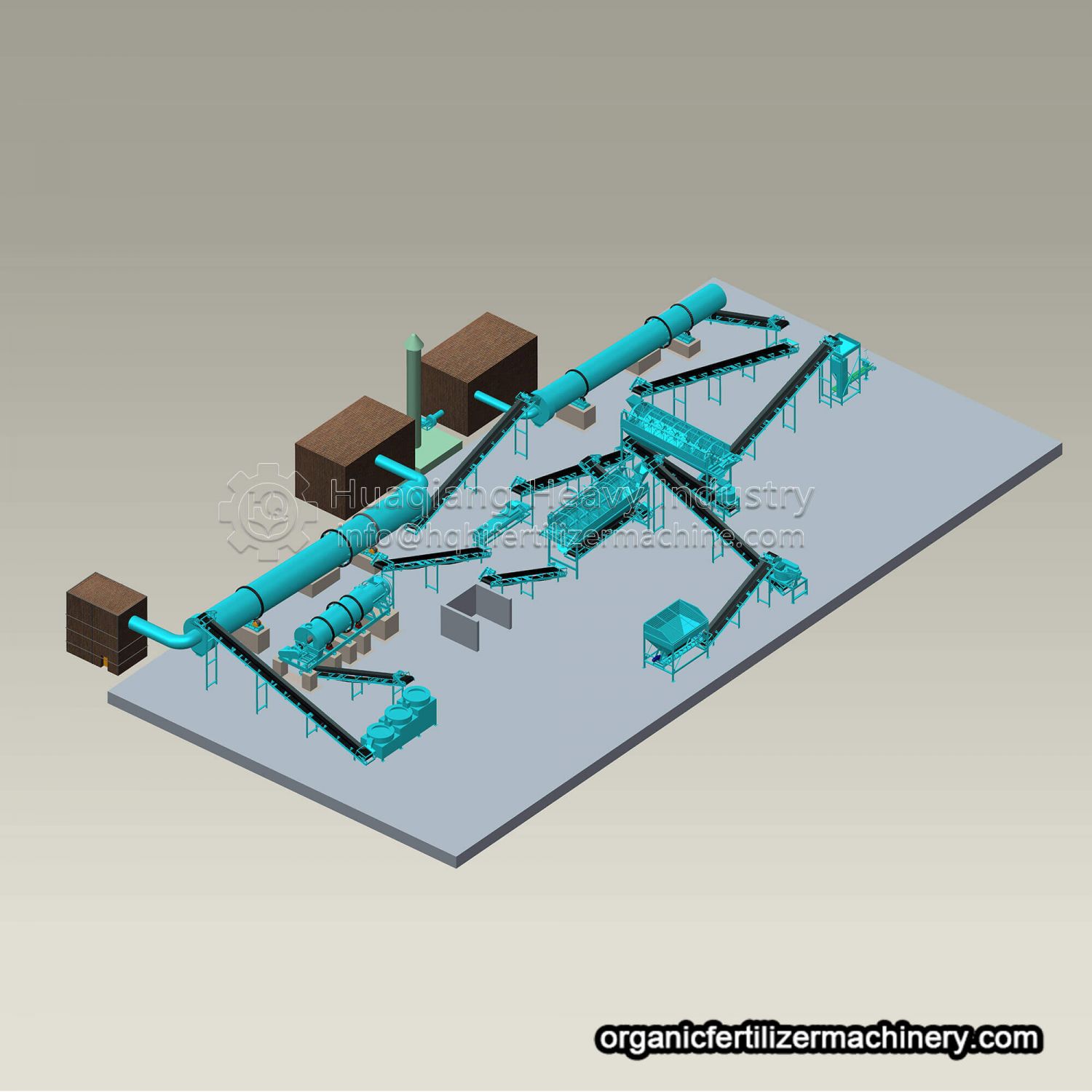

The main production steps of powdery

organic fertilizer production line are premixing, turning over and refining. The equipment configuration of powdered organic fertilizer is simple and the investment cost is low. For the small-scale powdered fertilizer production line from raw material fermentation to finished product packaging and warehousing, the fertilizer production machine is about 60000-70000 yuan.

Processing and production of 30000 T / a powdery

organic fertilizer production line

1. Heap fermentation

The trough type compost turning machine is used to overturn the strip pile. When the temperature rises to above 55 ℃, turn the pile every 1 ~ 2 days. After fermentation at 55 ℃ for 10 ~ 15 days, put away the pile. (the purpose of turning the pile is to promote the evaporation of water, the entry of oxygen into the pile, and the entry of bacteria into the pile for rapid propagation and fermentation.)

2. Material crushing

Fermented materials can not be sold directly as commodities, because long-term stacking will cause caking and other phenomena. At this time, the remaining bulk materials need to be finely crushed by a high moisture material crusher to obtain powdered organic fertilizer. (for the early stage fermentation of the powder fertilizer production line, in order to speed up the fermentation process, the auxiliary materials can be added to the crushing

fertilizer production machine for crushing.)

3. Screening and classification

In order to improve the appearance, get powdery organic fertilizer, re screening, get uniform powdery materials can be packaged. After the operation according to the above steps, the pure powdery organic fertilizer will be formed after being screened by the drum screening machine.

4. Finished product packaging.

The powdered organic fertilizer can be directly put into storage and sold after being packaged by the automatic packaging scale.