| Model | Capacity(t/h) | Power(kW) |

| BST-250 | 2-3 | 7.5 |

| BST-300 | 3-4 | 11 |

| BST-350 | 4-5 | 15 |

| BST-400 | 5-6 | 18.5 |

| BST-500 | 6-8 | 22 |

This series of polishing machines is a new type of equipment: the granulating rate is more than 95%. The motor adopts flexible belt drive to start smooth, slow down the impact force and improve the service life of the equipment.

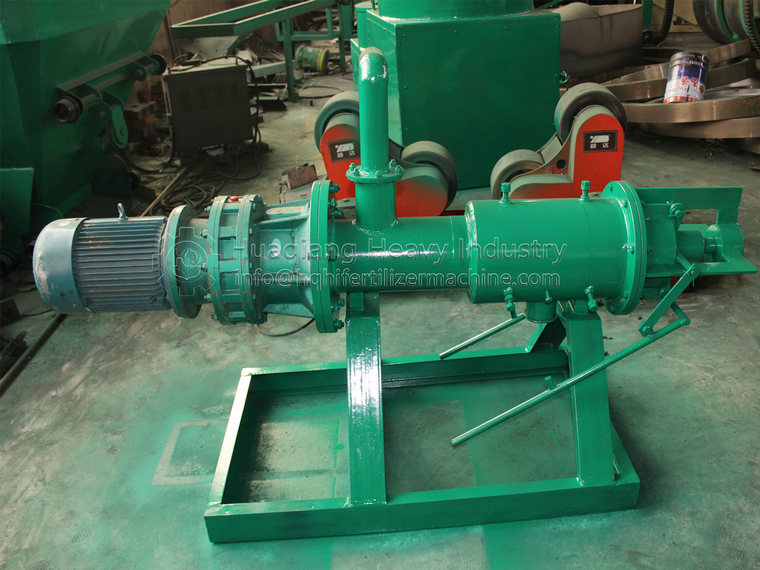

The machine is a new type of feeder. Its characteristic is that the shaft end of the reducer drives the stirring shaft to run. The stirring shaft has a fixed stirring tooth, and the stirring shaft drives stirring to make the material fully mixed.

Dust collector is a type of dust removal device. Each component of the dust collector has a certain size ratio. Each change in the proportional relationship can affect the efficiency and pressure loss of the dust collector.