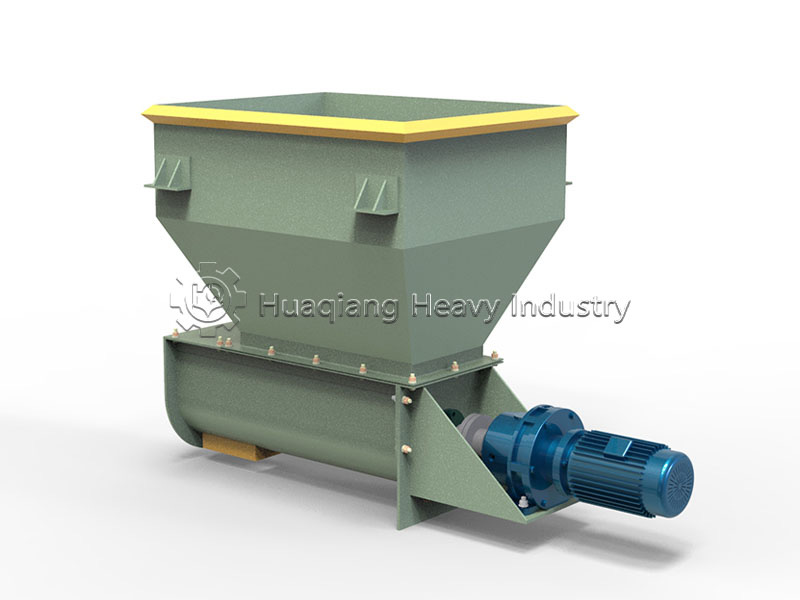

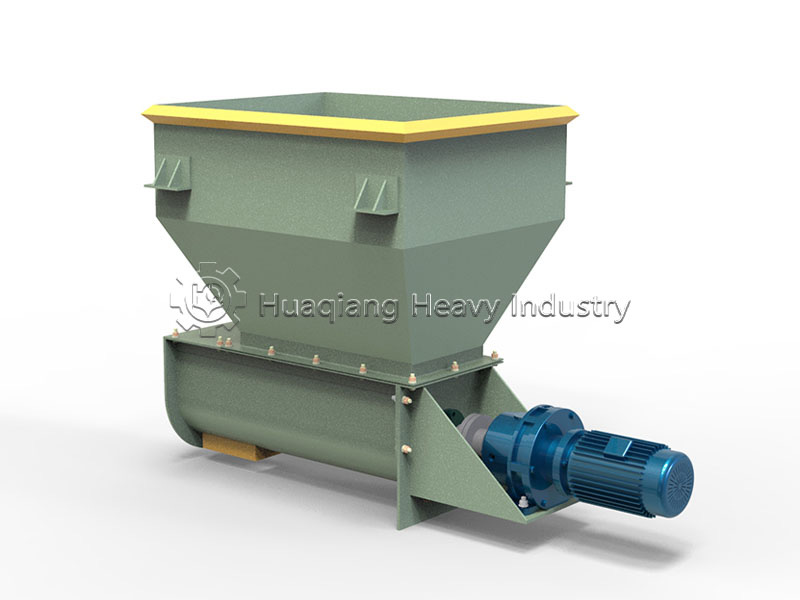

A uniform feeder is a device used in industrial production to ensure that materials enter subsequent processing equipment at a stable and uniform rate. Widely used in industries such as food, chemical, pharmaceutical, plastic processing, and mining, its main function is to avoid production fluctuations caused by uneven material supply, thereby improving production efficiency and product quality.

The uniform feeder mainly consists of the following parts:

Feed inlet: an open structure designed to receive materials and facilitate their flow in.

Feeding mechanism: This is the core part of a uniform feeder, commonly used in spiral feeders, vibrating feeders, belt feeders, etc., used to control the uniform flow of materials.

Regulating device: including speed controller, gate, etc., used to regulate the feeding rate and ensure the stability of material supply.

Drive system: provides power for the feeding mechanism, including motors, reducers, etc.

Framework and support structure: used to support the entire feeder and ensure stable operation of the equipment.

Control system: including PLC or microcomputer control system, used to monitor and adjust feeding rate, achieve automation control.

The working principle of a uniform feeder is to control the flow rate of materials through the movement of the feeding mechanism. Taking the spiral feeder as an example, the material enters from the feeding port, and the spiral feeder rotates under the drive of the motor. The spiral blades push the material forward, and the speed of the spiral feeder is controlled by an adjusting device to achieve precise control of the material supply rate, ensuring that the material enters the subsequent equipment at a stable and uniform rate, avoiding material accumulation or interruption, and ensuring the continuity and stability of the production process.

Precise control: By adjusting the device, the feeding rate of materials can be precisely controlled to ensure the uniformity and stability of material supply.

Strong adaptability: able to handle various types of materials, including powders, particles, flakes, etc., suitable for different industrial production environments.

Automated operation: Equipped with advanced control systems, it can achieve automated feeding processes, reduce manual intervention, and improve production efficiency.

Easy to maintain: The structural design is reasonable, easy to clean and maintain, reduces downtime, and lowers maintenance costs.

Energy saving and efficient: Adopting energy-saving design, reducing energy consumption, and improving feeding efficiency can help reduce production costs.

This series of polishing machines is a new type of equipment: the granulating rate is more than 95%. The motor adopts flexible belt drive to start smooth, slow down the impact force and improve the service life of the equipment.

Dust collector is a type of dust removal device. Each component of the dust collector has a certain size ratio. Each change in the proportional relationship can affect the efficiency and pressure loss of the dust collector.

Gas/Oil Hot Air Stove,n the drying process and the wet granulation process, the hot air stove is a necessary related equipment, which provides the necessary heat source for the drier system.