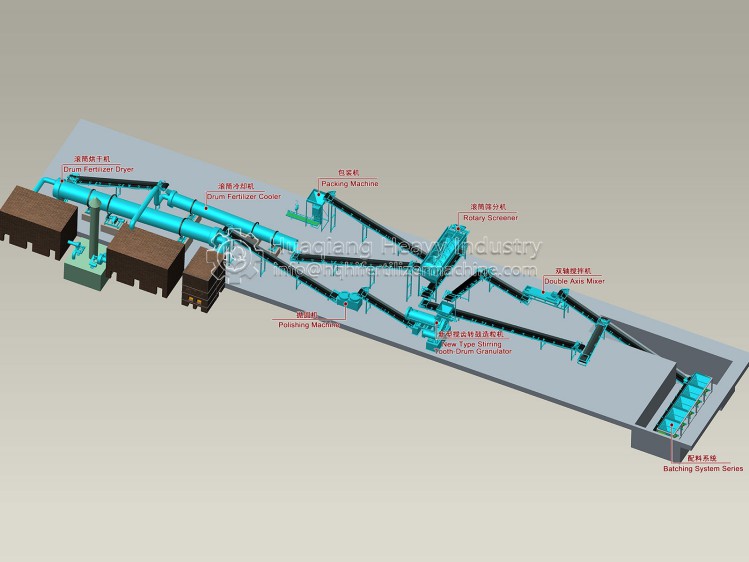

The roller press granulator production line is favored in the field of fertilizer granulation due to its low consumption and high efficiency. If the raw materials have been pre-treated, you can directly use the batching system as the starting point to build a set of streamlined, collaborative and efficient production lines to make the granulation process smoother.

The automatic batching system is the core starting point of the production line. It consists of conveying equipment and intelligent control systems, which can accurately control the ratio of various basic raw materials and additives, and support the simultaneous batching of multiple materials. After setting the formula, the system automatically adjusts the conveying amount of each material to ensure uniform mixing, avoid errors in manual batching, and provide high-quality raw materials for stable granulation.

The core granulation equipment determines the granulation effect. As a key equipment, the double roller press granulator directly presses the mixed raw materials into granules through the extrusion force generated by the relative rotation of the two rollers. It has a good granulation effect, does not need to add binders, and can retain the activity of the raw materials themselves. The matching crushing and shaping machine can process the extruded materials to make the granule shape more regular and improve the appearance of the finished product.

Post-processing equipment improves the quality of the finished product. The drum screener machine can quickly separate qualified or unqualified particles. Qualified particles enter the dryer, and unqualified particles can be returned to the granulation stage through the return system to reduce the waste of raw materials; the dryer controls the moisture content of the particles within a suitable range, and the cooler can reduce the temperature of the particles to a suitable level to prevent moisture absorption and agglomeration; the automatic packaging machine completes the final weighing and sealing, and adapts to packaging requirements of different specifications.

The entire production line is fully automated from ingredients to finished products, with a compact equipment layout, which can save site space and meet environmental protection requirements. Make the granulation process more streamlined and the cost more controllable, and easily achieve efficient production of granular fertilizers.