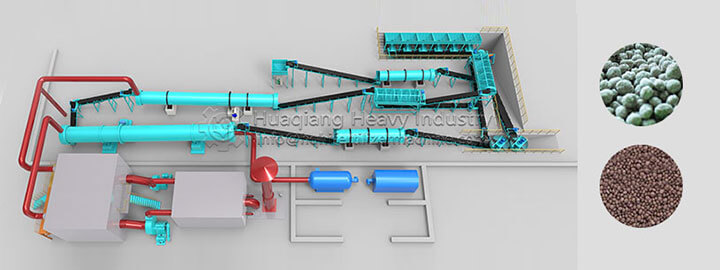

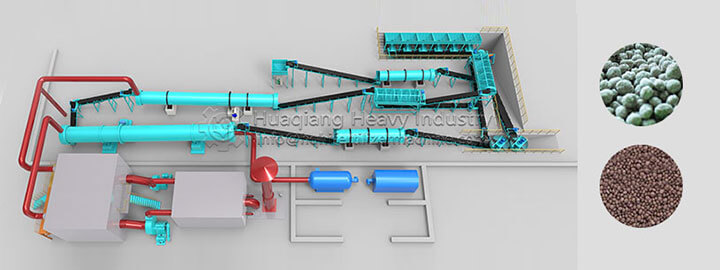

We produce the organic fertilizer granulator using the fertilizer manufacturing technology,and we design the organic fertilizer production line to make the organic fertilizer granulator ,in the line it equipped with different type fertilizer machines.How to work of these fertilizer machines in the lne?Supporting equipment for the production line with an annual output of 50000 tons of cow manure processing organic fertilizer:

The two in one new type organic

fertilizer granulator machine is composed of the body part,the pelletilizing rotor part and the transmission part,which is the most important part of the complete equipment of the series of organic fertilizer production line.In addition to the fertilizer granulator machine,other supporting equipment include stacker,crusher,dryer,screening machine,mixer,coating machine,packaging machine,and fertilizer conveyor machine and so on.

Working principle of the production line for processing organic fertilizer with an annual output of 50000 tons of co manure:

Drum granulator is a kind of forming maching which can make materials into specific shapes.The drum granulator is one of the key equipment in the

npk,compound fertilizer production industry,which is suitable for cold and hot granulation and large scale production of high medium and low concentration compound fertilizer.The main working mode is wet granulation of pellets.Through a certain amount of water or steam,the help of the roating motion of the cylinder,the extrusion pressure between the particles of the material can be generated to agglomerate into a ball.

The rotary drum granulator uses the mechanical stirring force of high-speed rotation and the resulting aerodynamic force to comtimuously realize the mixing,granulation,spheroidization,densification and other processes of fine powder materials in the granulator,so as to achieve the purpose of granulation.The pelletilizing method makes the pelletilizing rate of the particles higher,the particles more beautiful,and the engery is saved at the same time.

The rotary drum granulator is especially suitable for the granulation of light and fine powder materials.The finer the basic particles are,the higher the sphericity of the particles is and the better the quality of the pellets is.It is generally required that the particle size of the material before granulation should be less than 200 mesh.Typical application materials:chicken manure,pig manure,cow manure,tanli,clay,kaolin and so on.

In the

organic fertilizer manufacturing process to make the organic fertilizer granulator using the suitable fertilizer granulator machine and know the working method will help the fertilizer producers to producer the organic fertilizer granulator better.The rotary drum granulator machine is the suitable fertilizer granulator machine to make the cow manure into organic fertilizer granulator.The working principle of the rotary drum granulator is also not so complex.

We are designing the new method of producing the organic fertilizer granulator or bioorganic fertilizer granulator using the

bio fertilizer production line,we are as the fertilizer machine manufacturers,we are not only produce the fertilizer machines,we also design the new fertilizer machines and new fertilizer production lines for different raw materials that making these machines can be suitable for different methods.