The production methods of comprehensive granular compound fertilizer mainly include the following:

1. Slurry method

Phosphoric acid and ammonia are used as raw materials, and the neutralized slurry is coated and granulated in the ammoniated granulator using a neutralizer and a tubular reactor. Part of the nitrogen and potassium are added during the production process through the

npk fertilizer production line. Other substances are dried, sieved, and cooled to obtain NPK compound fertilizer products. This is a production method commonly used by major fertilizer companies and factories at home and abroad for large-scale production.

Phosphoric acid can be obtained by decomposing phosphate rock with sulfuric acid, and commercial phosphoric acid can also be purchased directly when conditions permit, in order to reduce investment and simplify production links. The advantage of this method is that it can produce both ammonium phosphate and NPK fertilizer. It also makes full use of the neutralization heat of acid and ammonia to evaporate the water content of the material, reduce the granulation water content and drying load, and reduce energy consumption. This method is used in The advantages of the

fertilizer production line are: large production scale, low production cost, good product quality, and high product strength.

Since it is usually necessary to construct a phosphoric acid plant and a sulfuric acid plant, the construction not only requires a large investment and a long period, but also involves the supply of phosphorus and sulfur resources and many environmental protection issues (such as phosphogypsum, fluorine, acid foam, acid mud, etc.). It is suitable for phosphate ore processing bases and large-scale production with few products. If purchased commercial phosphoric acid is used as a raw material, the current stable source and transportation issues and price factors have to be considered. In recent years, due to the improvement of the technology and equipment of China's phosphoric acid industry, wet-process phosphoric acid has entered the market as a commodity. The establishment of phosphoric acid bases in regions with resources and conditions to meet the needs of other regions for the development of high-concentration phosphate compound fertilizers with commercial phosphoric acid is forming a new way of thinking and ways. Market demand will surely promote the development of this industry, and It will definitely solve the demand for raw material phosphoric acid in many regions.

2. Solid agglomerate method

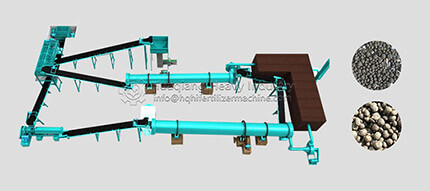

Using monomer basic fertilizers such as: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate monoammonium phosphate, diammonium phosphate, heavy calcium, ordinary calcium), potassium chloride (potassium sulfate), etc. as raw materials, they are crushed to After a certain degree of fineness, the material is agglomerated and granulated in the rolling bed of the

Double Roller Granulator (or disc granulator) through humidification and heating. During the granulation process, it can also be granulated in the drum if conditions permit. The machine adds a small amount of phosphoric acid and ammonia to improve the granulation conditions. The granulated materials are dried, sieved, and cooled to obtain NPK compound fertilizer products, which is also one of the methods widely used internationally.

This method has a wide range of sources of raw materials, simple processing process, low investment, low production cost, quick start-up, high production flexibility, simple and easy product grade adjustment, and strong versatility. The raw materials used are solid, and the raw materials are all solid. The reliance is not strong. Because it is the secondary processing of basic fertilizers, there is almost no environmental pollution problem. Since most of the basic fertilizers in my country are powder and granular, most of the small and medium-sized compound fertilizer plants in my country adopt this method.

Zhengzhou Huaqiang Heavy Industry Technology Co.Ltd has developed and produced complete set of equipment for the Fertilizer Production Line,

NPK Production Line, NPK fertilizer production Line and BB fertilizer production Line. We have Double Roller Granulator and all kinds of fertilizer granulator.