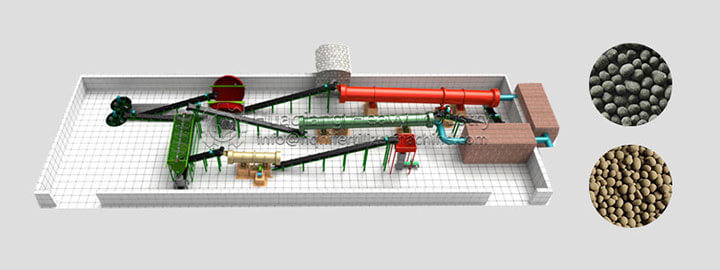

Producing the organic fertilizer using the fertilizer manufacturing technology not only can improve the working efficient,it also improves the rate of the raw materials.Producing the organic fertilizer granulator which using the

fertilizer granulator machine,can use different type raw materials which it contains a lot of organic materials.There we share the process of how to produce the organic fertilizer granulator using the crop straw.

1.Production and processing of refined organic fertilizer from plant residues

It is the simplest way to produce organic fertilizer by using plant residue to process and refine organic fertilzier.First,the plant residues are crushed into less than 3 cm materials by semi-dry pulverizer,then according to the nutrientional requirements of fermentation microorganisms(generally inoculated with high temperature bacteria),a variety of plant residues are compounded into culture materials,inoculated with microorganisms,through external auxiliary heating,a large amount of heat can be produced by fermentation with 4-5days,so that a large amount of water in the raw materials can be evaporated,deodorized and removed quickly water,low engery consumption,low production cost and economy.However,the fermentation maturity of this organic fertilizer is low.Once it is wet in water,it will easily lead to puterfaction and stink or insects.

2.Production and processing of bio organic fertilizer after fermentation of plant residues

Bio organic fertilizer is a kind of fertilizer with both microbial fertilizer and organic fertilizer effects,which is composed of specific functional microcattle(such as nitrogen fixing bacteria,phosphate dissolving bacteria,potassium dissolving bacteria,etc.)and organic materials formed by harmless and decomposed animal and plant residues(such as livestock manure,crop straw,etc.)The essential characteristic of bio organic fertilizer is that it contains high organic matter and microorganism with specific function.The microbe contained in the microbe has certain fertilizer effect ,such as improving soil fertility,fixing nitrogen in the air,assisting crops to absorb anti bacteria substances,which have good stimulation and regulation effect on the growth of crops,reducing or reducing the occurance of crop diseases and insect pests,and improving agricultural products quality.

Compared with the common organic fertilizer,which can be produced by the organic

fertilizer manufacturing process,the production technology of bio organic fertilizer is relatively high.In addition to adding biological agents to promote the maturity and decomposition of organic materials in the process of maturity,to achieve the purpose of direction maturity and deodorization,the product is also added with microorganisms with specific functions to improve the effect of the product.In order to produce this type of organic fertilizer,the first thing is to have the technology and ability to produce specific functional microorganisms.After a variety of plant residues are smashed,the compound fermentation microorganisms which are basically consistent with the biological characteristics of the specific microorganisms are selected.According to the characteristics of the compound fermentation microorganisms,the crushed plant residues are compound and add with a certain amount of inorganic compounds to make the fermentation culture materials.The tank type heap fermentation method,the flat type heap fermentation method,the fermentation tank fermentation method,the closed chamber fermentation method or the tower type fermentation method are adopted fermentation method and so on,the mature materials basically realize the harmless product which is conducive to the surrvival of functional bacteria added in the post-treatment process.In the post-treatment of fermentation materials,functional bacteria are usually added for compounding and shaping;the product dosage form in mainly powder,and granulation technology is also available,most of which use disk granulation ,less

roller press granulator.Particle products overcome the disadvantages of poor appearance and low level of powder products,improve the commodity of products,but also improve the production cost of enterprises,and have a certain impact on the surrvival of effective bacteria.